Introduction to Automatic Feeding CNC Lathes

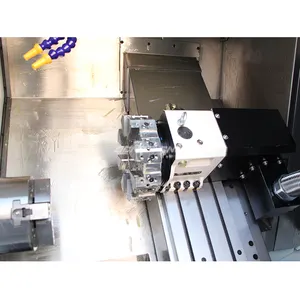

The realm of precision machining has been revolutionized by the advent of automatic feeding CNC lathes. These sophisticated machines serve as the backbone for industries requiring high-precision metal and wood turning operations. An automatic feeding CNC lathe is designed to automate the material shaping process, enhancing efficiency and consistency in production lines.

Types and Applications

There are various types of CNC lathes with automatic feeding mechanisms, each tailored for specific applications. From compact units ideal for small workshops to robust machines designed for metalworking, these lathes cater to a wide range of shaping tasks. They are pivotal in industries such as aerospace, automotive, and manufacturing, where precision and repeatability are paramount.

Features and Materials

CNC lathes with automatic bar feeders are equipped with features that allow for the seamless transformation of raw materials into finished parts. They can handle various materials, including metals, plastics, and wood, with precision. The integration of advanced software enables these machines to execute complex patterns and designs with minimal human intervention.

Advantages of Automation in CNC Machining

The primary advantage of an automatic CNC lathe is its ability to maintain consistent quality and high production rates. Automation reduces the potential for human error and allows for continuous operation, which is crucial for large batch production and meeting tight deadlines. Additionally, the automated feeding mechanism significantly reduces material wastage and enhances the overall efficiency of the machining process.

Choosing the Right CNC Lathe

Selecting the right CNC lathe with an automatic feeder involves considering the specific requirements of the task at hand. Factors such as the size of the lathe, the type of material to be shaped, and the complexity of the tasks should guide the decision-making process. Alibaba.com's platform facilitates this selection by offering a diverse range of options to meet the varied needs of different industries.

Conclusion

In conclusion, the integration of automatic feed mechanisms in CNC lathes has set a new standard in machining efficiency and precision. For businesses looking to enhance their production capabilities, investing in an automatic feeding CNC lathe could be a transformative step. Alibaba.com stands as a gateway to a wide array of machines that cater to the diverse needs of modern industries.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4