Popular in your industry

Related Searches:

Top categories

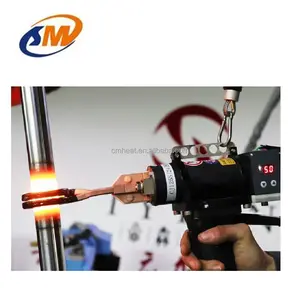

About portable induction heating machine

What is Induction Heating Machine (portable)

Induction heating machines are a type of equipment used to heat an electrical conductor by electromagnetic induction. This method of heating is based on the principles of Faraday's law of electromagnetic induction, which states that a magnetic field can induce an electric current when it interacts with a conductor. In the context of these machines, an alternating current is passed through a coil, creating a rapidly fluctuating magnetic field. When a metal object is placed within the coil, the magnetic field will induce eddy currents in the metal due to the phenomenon known as electromagnetic induction. These currents result in resistive heating of the metal, allowing it to be precisely heated for various applications.

Induction heating machines are designed for a wide range of users, from small workshops to large manufacturing plants. They are particularly useful for processes involving the hardening or annealing of metals, as well as for heating non-metallic materials such as ceramics. The portability of these machines makes them suitable for on-site operations, which is common in construction and repair projects.

The underlying technology of these machines involves a complex interplay of electrical fields and the magnetic properties of the metal being heated. The efficiency and effectiveness of the heating process depend on several factors including the frequency of the alternating current, the power of the current, and the characteristics of the metal being heated. By adjusting these parameters, operators can control the depth and area of heating, making this method highly versatile for different heating requirements.

Types of Induction Heating Machines (Portable)

The variety of portable induction heating machines available on Alibaba.com reflects the diverse needs of the modern market. Here is an overview of some common types:

-

The Handheld Induction Heater: A small yet powerful tool, the handheld induction heater is ideal for heating localized areas quickly. It is commonly used in automotive repair shops for tasks like loosening seized bolts or removing gears from shafts.

-

The Mini-Ductor Induction Heater: This type is perfect for smaller, more delicate work where less heat is needed. It's often used in electronics repair for tasks such as desoldering components or softening adhesives.

-

The Bearing Induction Heater: Specifically designed for heating applications related to bearings or other machinery with similar disassembling requirements, these units provide even and reliable heat to facilitate easy extraction.

-

The Portable Induction Heating Machine with Integrated Water Cooling: For intensive or prolonged tasks, such as heating large components or multiple pieces in quick succession, these machines feature built-in water cooling to manage temperature effectively.

-

The Magnetic Induction Heater: Utilizing magnetic fields, these heaters can penetrate through non-conductive materials to heat metal objects embedded within them. This is particularly useful for applications like brazing or soldering.

How to choose Induction Heating Machine (portable)

Selecting the right induction heating machine involves several considerations to ensure it meets your specific needs effectively. When evaluating potential options for your business, reflect on these aspects:

-

Frequency and Power Output: The frequency at which the machine operates and the amount of power it can output will impact how quickly and deeply it can heat materials. Understanding the heating requirements of your operations will guide you in choosing the most suitable machine.

-

Heating Coil Configuration: The arrangement of the coil within the machine affects how it interacts with your parts. A versatile machine with various coil configurations—like helical, solenoid, or clamshell—is preferable if you require flexibility across different workpiece geometries.

-

Control System Precision: The level of control you have over the precision of the heating process will influence the quality of your results. A more advanced control system—such as PLC or touch screen—may offer greater precision which is important for certain manufacturing standards.

-

Durability and After-Sales Service: Consider the build quality and reliability of the machine. It should be able to withstand continuous operation in industrial environments. Additionally, after-sales services like online support or availability of engineers can be critical for maintaining productivity.

By aligning your choice with these key factors and leveraging Alibaba.com's extensive range of suppliers offering various types of induction heating machines, you can find a solution that integrates seamlessly into your manufacturing processes.

About Induction Heating Machine (portable) on Alibaba.com

Alibaba.com stands out as an exceptional online marketplace where businesses can find a comprehensive selection of portable induction heating machines suitable for various industrial applications. With an extensive network of suppliers from around the globe, Alibaba.com facilitates the procurement process by offering detailed machinery test reports when available. This ensures that buyers have access to all necessary information regarding core components and key selling points like machine productivity and energy efficiency.

The platform's commitment to fostering international trade is evident through features that support easy mobile purchasing and multilingual communication. Furthermore, Alibaba.com's Trade Assurance service provides peace of mind by protecting payments until delivery is completed. By connecting with suppliers from different regions through Alibaba.com's robust interface, businesses can efficiently compare options and find a machine that aligns with their specific needs without compromising on quality or dependability.

Whether you're operating a small repair shop or managing a large manufacturing plant, Alibaba.com streamlines the process of acquiring the right portable induction heating equipment by offering tailored trading experiences that address the diverse requirements of business operations across various industries.

Common FAQs for Induction Heating Machine (portable)

What is the principle behind induction heating?

Induction heating works by creating an electromagnetic field that induces heat in a conductive material, such as a metal, through eddy currents. This method is energy-efficient and allows for precise heating without heating the entire workpiece.

What are the benefits of using an induction heating machine?

Induction heating machines offer rapid and uniform heating, precise temperature control, and are highly energy-efficient. They are suitable for a variety of heating applications in different industries.

Can induction heating machines be used for all types of metals?

Induction heating machines are versatile and can be used on a variety of metals, including aluminum, copper, and steel, as long as the metal is conductive.

How does the choice of frequency impact the induction heating process?

The frequency of an induction heating machine affects its ability to heat the material. Higher frequencies are typically required for more precise heating, while lower frequencies are used for deeper penetration.

What is the role of core components in induction heating machines?

Core components such as motors, PLCs (Programmable Logic Controllers), gearboxes, and pumps are crucial in ensuring the induction heating machine operates efficiently and accurately.

Are there different types of induction heating machines for specific industrial applications?

Yes, there are various types of induction heating machines designed to meet specific industrial applications, such as full automatic machines for mass production environments or handheld devices for repair and maintenance work.

How do I determine the right size induction heating machine for my business?

Consider the volume of work you need to handle, the size of the materials to be heated, and the desired speed and efficiency of the process. These factors will help determine the appropriate machine size for your business.

What should I look for in terms of after-sales service when purchasing an induction heating machine?

Look for suppliers who offer comprehensive after-sales services such as online support, video technical support, and engineers who can service machinery overseas. This ensures you have access to assistance throughout the lifetime of your equipment.

Does the core component brand matter when selecting an induction heating machine?

Yes, the quality and brand reputation of the core components can impact the performance and durability of the induction heating machine. It's important to choose reliable suppliers with good track records.

How important is local service availability when purchasing an induction heating machine?

Local service availability is crucial as it ensures that you can quickly source maintenance and repair services when needed. It's also beneficial if the supplier has a service center in your region for prompt technical support.

Can I find customized induction heating machines for specific applications?

Many suppliers offer customized solutions based on specific heating requirements or industry standards. It's best to discuss your particular needs directly with suppliers to find a machine that fits your application.