Introduction to Silicone Rubber Mixers

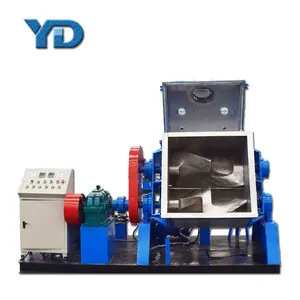

Silicone rubber mixers are essential industrial equipment designed for the efficient and uniform mixing of silicone rubber compounds. These machines are pivotal in various sectors, including automotive, medical, and electronics, where precision and consistency in rubber mixing are paramount. The silicone rubber mixing machine stands as a testament to the advancements in material processing technology.

Types and Applications

The diversity of silicone rubber mixers includes several types, such as the two-roll mill, internal batch mixers, and continuous mixers, each serving distinct production requirements. From small-scale laboratory settings to high-volume industrial applications, these machines cater to a broad spectrum of rubber milling tasks. The silicone rubber compound mixer, for instance, is tailored for intricate mixing processes, ensuring a homogenous blend of materials.

Features and Materials

A silicone rubber mixing machine is constructed with robust materials that withstand the rigors of milling operations. Stainless steel and hardened alloys are commonly used for their resistance to wear and corrosion. Features such as variable speed settings, temperature control, and automated cutting-edge systems enhance the functionality of a silicone rubber compound mixer. These features contribute to the precise control over the mixing process, ensuring the consistency of the final product.

Advantages of Modern Mixers

Modern silicone rubber mixers offer numerous advantages. Their efficiency in material handling and energy consumption translates into cost savings and a reduced environmental footprint. The design of a typical silicone rubber mixing machine prioritizes user safety and ease of maintenance, with many models featuring easy-to-clean surfaces and safety interlocks. The operational efficiency of these mixers is a crucial factor in increasing the productivity of manufacturing processes.

Choosing the Right Mixer

Selecting the appropriate silicone rubber mixer requires an understanding of specific production needs. Factors such as batch size, material properties, and desired throughput must be considered. A high-capacity silicone rubber mixing machine may be ideal for large-scale production, while precision mixers are better suited for tasks requiring meticulous attention to detail.

Conclusion

In conclusion, the silicone rubber mixer category encompasses a range of machines designed to meet the demands of various industries. The silicone rubber mixing machine is a critical investment for businesses looking to enhance their production capabilities. With a focus on durability, efficiency, and versatility, these mixers are engineered to deliver consistent results, ensuring that every mixing task is completed to the highest standards.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4