Popular in your industry

Top categories

About yogurt processing equipment

Introduction to Yogurt Processing Equipment

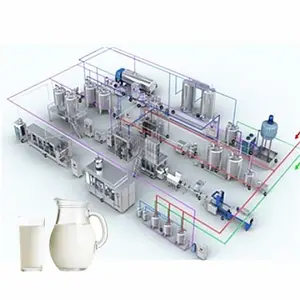

The dairy industry is a cornerstone of agricultural production, with yogurt standing out as a nutritious and versatile product. Yogurt processing equipment is at the heart of this sector, serving a critical role in transforming milk into yogurt through a series of controlled processes. This category encompasses a variety of machines designed for different scales of production, from small artisanal batches to large-scale commercial manufacturing.

Types of Yogurt Processing Machinery

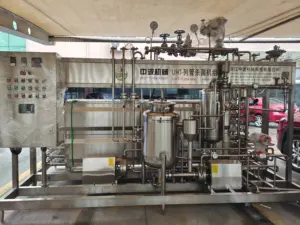

Diverse in form and function, yogurt processing machinery includes pasteurizers, homogenizers, fermenters, and chilling tanks. Each piece plays a specific role in ensuring the milk is safely and effectively converted into yogurt. Pasteurizers are used to heat the milk to eliminate pathogens, while homogenizers ensure a uniform texture. Fermenters provide the controlled environment necessary for bacterial cultures to convert lactose into lactic acid, which gives yogurt its distinctive tang. Chilling tanks then cool the product down, halting the fermentation process at the optimal time.

Applications and Features

Yogurt processing equipment is designed to meet the needs of various dairy processing activities. Its applications range from producing traditional set yogurt to stirred or drinking yogurt varieties. The features of this equipment are tailored to enhance efficiency, with some machines offering automated control systems for precise temperature and fermentation management. The design of these machines typically prioritizes durability and ease of cleaning, ensuring compliance with food safety standards and extending the equipment's service life.

Materials and Advantages

Constructed from materials like stainless steel, yogurt processing equipment is built to withstand the acidic environment of yogurt production and the rigorous cleaning protocols necessary in food processing. The advantages of using specialized yogurt processing machinery include consistent product quality, increased production capacity, and the ability to maintain the nutritional properties of the yogurt through careful handling of the product during processing.

Enhancing Dairy Farm Efficiency

Integrating modern yogurt processing equipment into dairy operations can significantly enhance overall efficiency. These machines are engineered to maximize output with minimal manual effort, allowing dairy farmers to meet the growing global demand for dairy products. By optimizing the yogurt production process, dairy businesses can improve their product output and food standards, contributing to a more sustainable and profitable operation.

Conclusion

Yogurt processing equipment is a vital investment for dairy businesses aiming to scale up production and meet the nutritional needs of their customers. With a variety of machines available, each dairy operation can find the equipment that best suits its production requirements. By selecting the appropriate yogurt processing machinery, dairy processors can ensure a smooth, efficient, and hygienic production process.