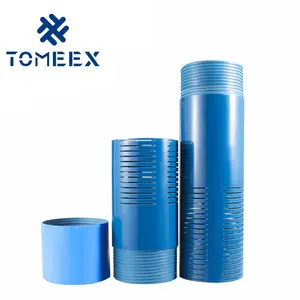

Understanding the 160 mm PVC Reducer

A 160 mm PVC reducer is a crucial component in the realm of pipe systems, designed to connect pipes of varying diameters seamlessly. This fitting is essential in both commercial and residential plumbing, ensuring a smooth transition and maintaining the integrity of the flow within the system.

Types and Applications

The PVC pipe reducer comes in various types to suit different applications. Whether it's for water supply, waste disposal, or irrigation, the reducer ensures a leak-proof connection between pipes of different sizes. Its versatility makes it suitable for a wide range of industries, from construction to agriculture.

Material Advantages and Features

Made from polyvinyl chloride, the PVC reducer coupling boasts features that cater to efficient fluid conveyance. Its smooth inner walls reduce resistance, allowing for an unimpeded flow. The lightweight nature of PVC also facilitates easier handling and installation, while its cost-effectiveness makes it an economical choice for extensive piping networks.

Complementary Components

In addition to the PVC pipe fittings reducer, other components like P-traps and pipe caps play significant roles in a comprehensive pipe system. P-traps are essential for maintaining hygiene by preventing sewer gas entry, and pipe caps are integral for terminating lines or protecting threads.

Selection Criteria Based on Usage

Selecting the right PVC reduction involves understanding the nature of the fluids in the system. For industrial applications, the reducer must withstand the chemical properties of the conveyed substances, ensuring durability and reliability.

Environmental Resistance

While the PVC reducing fitting is suitable for a variety of environments, other materials like copper are preferred for their corrosion resistance, especially in underground applications. The choice of material is dictated by the specific requirements of the environment in which the pipe system will operate.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4