Popular in your industry

Related Searches:

Top categories

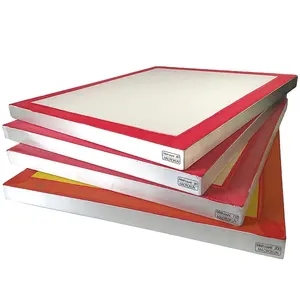

About 165 mesh printing screen

Introduction to 165 Mesh Printing Screen

The 165 mesh printing screen is a pivotal tool in the screen printing industry, designed to cater to detailed and fine printing requirements. This specific mesh count offers a balance between ink deposit and resolution, making it suitable for a variety of applications. The construction of these screens involves a precise weaving process that ensures uniformity and durability, which are essential for consistent print quality.

Types and Applications

Different types of screen printing mesh are tailored for various printing jobs. The 165 mesh count is particularly versatile, commonly used in textile printing, graphics, and industrial applications where detail and ink control are necessary. Its ability to produce sharp images while still allowing a fair volume of ink to pass through makes it a preferred choice for printing on fabrics, glass, and other substrates.

Features and Materials

The polyester screen printing mesh is renowned for its strength and elasticity. The 165 mesh is typically made from high-tensile polyester, providing resistance to chemicals and moisture. This resilience is crucial for maintaining the tension of the mesh throughout the printing process, which is key to achieving high-quality prints.

Advantages of Using 165 Mesh

Utilizing a 165 mesh count comes with several advantages. It allows for a high level of detail in printed designs while maintaining good ink coverage. The fine threads ensure a smooth ink deposit, which is essential for creating sharp and clear images. Moreover, the durability of the mesh means it can withstand the rigors of the printing process, making it a cost-effective option for printers.

Considerations for Selection

When selecting a screen printing fabric mesh, it's important to consider the type of ink and the substrate being used. The 165 mesh is well-suited for thinner inks and provides a smooth finish on a variety of materials. It's also crucial to consider the frame and tensioning system to ensure the mesh can be stretched properly for optimal printing results.

Maintenance and Longevity

Maintaining a screen printing screen is key to its longevity. Proper cleaning, storage, and handling can significantly extend the life of a 165 mesh screen. It's important to follow the correct procedures to avoid damage to the mesh and to ensure it remains in good condition for future print runs.