Popular in your industry

Top categories

About 3d printer homemade

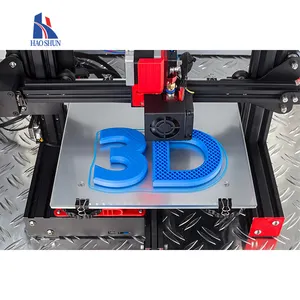

Introduction to Homemade 3D Printer

Homemade 3D printers have gained popularity among DIY enthusiasts and small-scale businesses for their affordability and customization options. These printers, also known as home made 3D printers, allow users to create three-dimensional objects from various materials using additive manufacturing technology. Whether you are a hobbyist, educator, or small business owner, a homemade 3D printer can be a valuable tool for bringing your ideas to life.

Technical Specifications

When considering a homemade 3D printer, it is essential to look at technical specifications such as build volume, layer resolution, printing speed, and material compatibility. The build volume determines the maximum size of the objects you can print, while layer resolution impacts the level of detail in your prints. Additionally, printing speed can affect production efficiency, especially for business use. Compatibility with different types of filaments like PLA, ABS, or even metal filaments expands the versatility of the printer.

Design and Features

The design of a homemade 3D printer can vary based on the builder's preferences and budget. Some DIY enthusiasts opt for open-source designs, while others create custom frames using materials like aluminum or steel for enhanced durability. Features such as heated beds, dual extruders for multi-material printing, and auto-leveling systems contribute to the printer's functionality and print quality.

Advantages of Homemade 3D Printers

One of the primary advantages of homemade 3D printers is the cost-effectiveness compared to commercial models. By building your own printer, you can save money on the initial investment and customize the machine to suit your specific needs. Moreover, DIY printers offer a great learning experience, allowing users to understand the intricacies of 3D printing technology and make modifications as desired.

Choosing the Right Homemade 3D Printer

When selecting a homemade 3D printer, consider factors like your budget, printing requirements, technical skills, and desired features. If you are new to 3D printing, starting with a beginner-friendly DIY kit can be a good option. Advanced users may prefer to source individual components and build a customized printer based on their expertise and project demands.

Use Scenarios and Applications

Homemade 3D printers find applications in various industries and fields, including rapid prototyping, product development, education, and art. Small businesses can use DIY printers for in-house production of custom parts and prototypes, saving time and outsourcing costs. Educators can leverage homemade 3D printers to teach students about design, engineering, and manufacturing processes.

Maintenance and Upkeep

Proper maintenance is crucial for ensuring the longevity and performance of a homemade 3D printer. Regular cleaning of the print bed, nozzles, and extruders can prevent clogs and defects in printed objects. Calibrating the printer's settings and replacing worn-out parts promptly can help maintain print quality. Additionally, staying updated on firmware upgrades and software enhancements is vital for optimal printer operation.

Conclusion

In conclusion, homemade 3D printers offer a cost-effective and customizable solution for individuals and businesses looking to explore the world of additive manufacturing. By understanding the technical specifications, design options, advantages, and maintenance requirements of DIY printers, buyers can make informed decisions when investing in a homemade 3D printer for their projects and production needs.