Introduction to 4m40 Engine Crankshaft Pulley

The 4m40 engine crankshaft pulley is an integral component in the automotive engine system, playing a pivotal role in harmonizing the mechanical functions of an engine. This pulley is part of the engine's bottom end, connecting to the crankshaft, and is responsible for driving various belts that operate critical engine components.

Types and Applications

There are various types of 4m40 crankshaft pulleys, each designed to meet the specifications of different engine models. These pulleys are primarily used in automotive engines but can also be found in industrial machinery where precise engine timing and belt integration are necessary.

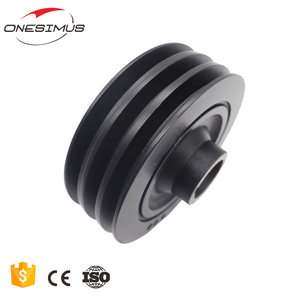

Features and Materials

The 4m40 engine crankshaft pulley is known for its robust construction, typically made from durable materials like iron or aluminum. These materials ensure longevity and consistent performance. The design of the pulley allows for the redirection of force in multiple directions, enhancing the engine's mechanical advantage.

Advantages of the 4m40 Crankshaft Pulley

Utilizing a 4m40 crankshaft pulley in an engine setup contributes to a smoother operation by supporting movements and managing tension effectively. This pulley system requires minimal lubrication, which reduces maintenance needs and costs. Moreover, it is engineered to perform tasks without storing energy, minimizing the risk of injury from sudden movements or drops.

Selection and Customization

Alibaba.com offers a diverse array of 4m40 engine crankshaft pulleys, including options for customization. Buyers can communicate with suppliers to discuss modifications or custom designs to meet specific requirements, ensuring the right fit for their machinery or vehicles.

Operational Efficiency

The 4m40 engine crankshaft pulley is designed to facilitate efficient force application, making it easier to handle heavy loads with reduced effort. Its construction does not necessitate frequent maintenance, providing a cost-effective solution for engine management.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4