Popular in your industry

Top categories

About aluminum extrusion mold

Understanding Aluminum Extrusion Tooling

Aluminum extrusion tooling, a process pivotal to shaping aluminum into specific cross-sectional profiles, is indispensable across industries such as automotive, construction, and aerospace. Known also as dies, this tooling is integral to producing parts with uniformity and a superior finish, crucial for a multitude of applications.

In aluminum extrusion, the aluminum is propelled through a die, which molds it into the requisite shape. Subsequently, the material is cooled and trimmed to the desired length. The precision of the die's design is paramount, as it determines the final profile of the extruded product. The tooling must resist the considerable heat and pressure of extrusion without warping or failing.

Each set of aluminum extrusion tooling is customized to meet the unique needs of the client, taking into account the aluminum alloy, temper, and profile complexity. Custom tooling may be crafted for particular shapes or uses. Experts in aluminum extrusion, including engineers and manufacturers, utilize this tooling to deliver top-notch extrusions.

For entities in the aluminum extrusion sector, grasping the intricacies of these tools is essential to producing items that adhere to stringent specifications and perform as intended.

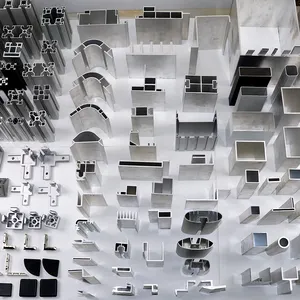

Varieties of Aluminum Extrusion Tooling

Diverse tooling types are employed within aluminum extrusion to address manufacturers' distinct requirements:

-

Die Casting: Employed for intricate, high-precision shapes, die casting involves pouring molten aluminum into a steel mold, which solidifies into the end product. This method is favored for creating parts with robust structural integrity and intricate details, such as in automotive parts and electronic casings.

-

Plastic Extrusion Mould: While not metallic, plastic extrusion tooling is mentioned here for its role alongside aluminum extrusion in fabricating composite profiles. These moulds are adept at forming consistent plastic shapes in materials like PP or PVC, serving sectors from construction to transport.

-

Temper: The term 'temper' in extrusion denotes the aluminum's hardness or strength, achieved by controlling the cooling rate post-extrusion. For example, a T6 temper is sought after for structural uses due to its robustness.

-

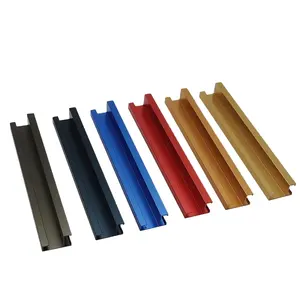

Surface Finish: Aluminum profiles can sport various surface finishes, from a basic mill finish to powder coating or anodizing, catering to both aesthetic and functional needs such as corrosion resistance.

-

Color: Aluminum extrusions can be rendered in an array of colors through powder coating or painting, providing designers with creative flexibility.

Each tooling type has its applications, shaped by the material properties it can mold and the profile specifications of the final piece.

Selecting Aluminum Extrusion Tooling

When choosing Aluminum Extrusion Tooling on Alibaba.com, companies should weigh several factors pertinent to their particular requirements:

-

Material Grade: The aluminum alloy grade selected should correspond with the application's demands. While the 6000 series is broadly applicable, certain sectors may require other series like the 7000 for enhanced strength or the 1000 for superior electrical conductivity.

-

Shaping Mode: The complexity and design of your product may necessitate different shaping modes, such as die casting or plastic extrusion moulds. Suppliers should offer advice on the most fitting shaping mode for your project.

-

Customization: Customization capabilities are vital for unique designs or dimensions. Seek suppliers providing CAD/CAM support for meticulous customization.

-

Application Support: Some Alibaba.com suppliers extend additional services like application assistance or material selection advice. Assess if these services would be advantageous for your endeavor.

Securing the right tooling transcends matching technical specifications; it involves partnering with a supplier capable of offering extensive support throughout the process.

Aluminum Extrusion Tooling on Alibaba.com

Alibaba.com presents a vast array of aluminum extrusion tooling options for businesses intent on manufacturing products to exacting standards. The platform's global scope connects purchasers with seasoned suppliers worldwide, ensuring a diverse selection of tooling that meets various aluminum alloy grades and specific features like color or surface treatment.

Alibaba.com's dedication to smooth trade is underscored by services like Trade Assurance, which safeguards payments until delivery confirmation. Such security measures enable companies to confidently invest in tooling, assured by Alibaba.com's reliable trade practices.

As a marketplace streamlining international trade, Alibaba.com not only offers a broad selection but also ensures ease of business on mobile devices and communication in multiple languages, reflecting its commitment to user convenience. Alibaba.com distinguishes itself as a vital resource for companies in search of premium aluminum extrusion tooling solutions tailored to their manufacturing needs, with verified supplier listings and a focus on simplicity.

Frequently Asked Questions on Aluminum Extrusion Tooling

What is the primary function of aluminum extrusion tooling?

Aluminum extrusion tooling is instrumental in fabricating a variety of profiles and shapes from aluminum alloys, utilized in sectors from construction to consumer goods. The tooling is key to achieving precision and efficiency in the extrusion process.

How does the aluminum material influence the quality of the extruded product?

The choice of aluminum material, such as the 6000 or 7000 series, affects the extruded product's mechanical characteristics, including strength and ductility. Selecting the appropriate material is critical for the tooling to yield the intended results.

Is it possible to tailor aluminum extrusion tooling to specific designs?

Indeed, aluminum extrusion tooling can be extensively customized to conform to particular design demands. Suppliers on Alibaba.com are equipped to produce tooling that aligns with your precise requirements.

What are the benefits of employing CNC machining for aluminum extrusion tooling?

CNC machining offers exceptional precision in the extrusion process and is capable of crafting complex shapes that might be challenging with conventional techniques.

How should I determine the appropriate aluminum grade for my extrusion project?

Choosing the suitable aluminum grade for an extrusion project involves evaluating the specific application, necessary mechanical properties, and any potential surface treatments to enhance functionality or aesthetics.

What surface treatments are applicable to aluminum extrusion tooling?

Aluminum extrusion tooling can undergo a variety of surface treatments, such as powder coating and polishing, to augment durability or visual appeal.

Can aluminum extrusion tooling be repaired if damaged?

Repairing aluminum extrusion tooling is feasible depending on the damage's severity and spare part availability, although significant damage might necessitate a complete replacement of the tool.

How does the design of an aluminum extrusion tool affect its performance?

The design of an aluminum extrusion tool significantly influences its performance. For example, T-profiles are optimal for construction materials, while square or round profiles may be preferred for decorative or structural support purposes.

Is it feasible to extrude multiple profiles with a single tooling set?

Extruding multiple profiles with one tooling set may be possible, contingent on the design's complexity and the extrusion machinery's capabilities.

Which industries frequently utilize aluminum extrusion tooling?

Aluminum extrusion tooling is widely employed in industries such as construction, automotive production, aerospace, consumer goods manufacturing, and in any field requiring bespoke aluminum shapes.

How does surface treatment impact aluminum extrusion tooling?

Surface treatments like powder coating or polishing can enhance the extruded product's appearance and performance. Typically applied post-extrusion, these treatments can also offer added protection against corrosion.

What considerations are important when selecting the size of aluminum extrusion tooling?

When choosing the size of aluminum extrusion tooling, it's important to consider the final product's dimensions and any specific size requirements or limitations. The tooling must be capable of accommodating the size and profile of the intended product.