Popular in your industry

Related Searches:

Top categories

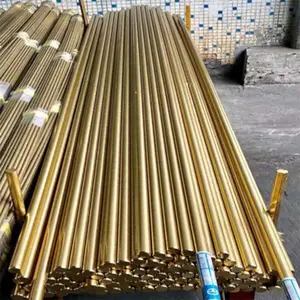

About bronze welding rods

Bronze Welding Rods: An Overview

Bronze welding rods are a specialized category of welding consumables designed for joining various metals, particularly in applications requiring corrosion resistance and metal-to-metal wear properties. These rods are commonly utilized in marine, industrial, and artistic applications due to their strength and durability.

Types and Applications

The versatility of bronze welding rods is evident in their wide range of types, such as silicon bronze tig rod and aluminum bronze tig rod, each tailored for specific welding processes and base metals. Silicon bronze rods are often used in TIG welding for their smooth flow and strong bond, making them suitable for welding similar or dissimilar metals, whereas aluminum bronze rods are preferred for their superior strength and resistance to corrosion.

Features and Materials

Bronze rod welding is characterized by its use of copper alloy materials, including variations like silicon bronze filler rod and silicon bronze brazing rod. These materials are selected for their ability to create strong, ductile joints and their resistance to corrosion. The addition of silicon in silicon bronze welding rod enhances fluidity and reduces melting temperature, which is beneficial in both welding and brazing applications.

Advantages of Bronze Welding

The primary advantage of using bronze tig welding rods is their resistance to saltwater corrosion, making them an ideal choice for marine applications. Furthermore, the bronze brazing rod offers excellent flow characteristics and can fill gaps effectively, which is crucial in repair work or when working with intricate designs.

Selection Considerations

When selecting a welding rod, factors such as the base metal, welding current, and metal thickness are crucial. For instance, aluminium bronze tig rods are well-suited for welding alloys with high tensile strength, while fluxed brazing rods are preferred for their self-fluxing capabilities, reducing the need for additional flux in certain brazing operations.

Complementary Welding Accessories

In addition to welding rods, a comprehensive selection of related accessories is available to complement the welding process. These include various types of brazing rods flux coated options, which are designed to enhance the brazing process by preventing oxidation and improving the flow of the filler metal.