CNC Metal Mould Making Machinery: An Overview

CNC metal mould making machinery stands as a cornerstone in the manufacturing sector, providing unparalleled precision in metalworking. This category encompasses a variety of machines designed for creating detailed and intricate moulds used in various industries, from automotive to aerospace. The machinery operates using Computer Numerical Control (CNC), which allows for the automation of metal shaping with high accuracy.

Types and Applications

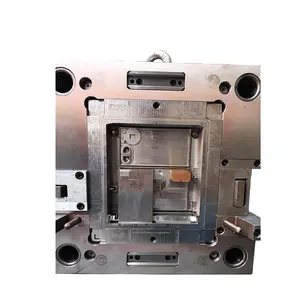

The applications of CNC metal mould making machinery are diverse, catering to tasks such as cutting, milling, and drilling with precision. These machines are integral in producing complex moulds for injection molding, die casting, and precision metal components. The versatility of CNC technology means these machines can be adapted for small-scale bespoke creations or large-scale industrial parts.

Features and Materials

CNC mould making machines are compatible with a wide range of materials, including aluminum, steel, and copper. They feature advanced software that translates design models into executable paths for the machine, ensuring each mould is crafted to exact specifications. The robust construction of these machines ensures durability and the ability to withstand the rigors of heavy metalworking tasks.

Advantages of CNC Mould Making Machinery

The adoption of CNC mould making technology in a production environment brings numerous advantages. The automation of the mould making process reduces the likelihood of human error, enhances production speed, and allows for the creation of complex designs that would be difficult to achieve manually. Additionally, the repeatability and consistency of output are significantly improved, ensuring uniformity across all produced items.

Selecting the Right Machinery

Choosing the appropriate CNC metal mould making equipment requires consideration of several factors, including the size of the machinery, power requirements, and the specific type of moulding tasks it will perform. Prospective buyers should assess the machine's compatibility with their intended materials and the complexity of the mould designs they intend to produce. It is also important to consider the machine's throughput rates and table configuration to ensure it meets production demands.

Integration with Production Lines

Integrating CNC metal mould machinery into existing production lines can streamline operations and increase efficiency. The machinery's ability to interface with other CNC equipment allows for a cohesive and automated production environment. This integration is crucial for industries looking to scale up their manufacturing capabilities while maintaining precision and quality.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4