Popular in your industry

Top categories

About computer cabinet making machine

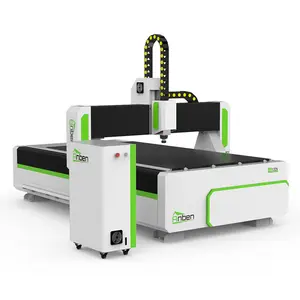

Introduction to Computer Cabinet Making Machines

The realm of woodworking has been revolutionized by the advent of computer cabinet making machines. These sophisticated devices are engineered to handle intricate tasks in wood processing, enabling the creation of precise and consistent cuts for a variety of applications. The category encompasses a diverse array of machinery designed to meet the specific needs of woodworkers and manufacturers, from crafting delicate furniture to robust cabinetry.

Types of Cabinet Making Machines

Within the woodworking industry, several types of CNC router machines are prominent. These range from large-scale industrial models to more compact, manual routers. Each type serves a unique purpose, with CNC routers being the cornerstone for high-volume production due to their programmable nature and automated capabilities. Other types include plunge routers, ideal for creating grooves and recesses, and fixed base routers, which excel in edge shaping. The versatility of these machines allows for a broad spectrum of woodworking projects, from simple to complex designs.

Applications and Features

The application of wood processing machinery extends across various woodworking projects. These machines are not only pivotal in the production of furniture and decorative frames but also play a crucial role in the construction of toys and intricate sculptures. Features such as power rating, cutting style, and throughput rates are critical to consider, as they directly impact the machine's performance in different woodworking scenarios. Additionally, the table configuration of these routers can significantly influence the precision and efficiency of the output.

Materials and Advantages

Wood shaping tools are designed to work with a wide range of materials, from softwoods to hardwoods, and even composite materials. The advantage of using a computer cabinet making machine lies in its ability to maintain consistency in production, which is particularly beneficial for businesses that require uniformity in their wood products. Furthermore, the precision offered by these machines minimizes material waste, thereby optimizing the manufacturing process.

Selecting the Right Machine

Choosing the appropriate woodworking router is a nuanced process that involves considering the specific needs of a project or production line. Factors such as the weight of the machine, its portability, and the complexity of tasks it can perform are all important considerations. For instance, a lightweight router may be ideal for on-site carpentry, whereas a more robust machine would be better suited for stationary, high-volume tasks in a workshop setting.

Conclusion

In conclusion, the wood router selection available caters to a wide spectrum of woodworking requirements. From portable devices for on-the-go carpentry to more stationary, sophisticated CNC machines for mass production, the range of computer cabinet making machines is designed to enhance efficiency and precision in woodworking. It is essential to assess the specific needs of your operation to ensure the selection of a machine that aligns with your production goals and material handling.