Popular in your industry

Top categories

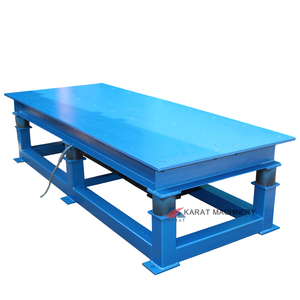

About concrete mold vibration table

Introduction to Concrete Mold Vibration Tables

Concrete mold vibration tables are essential tools in the construction and manufacturing industries, designed to enhance the compaction and solidity of concrete surfaces. These tables are crucial for ensuring the integrity and longevity of concrete structures by eliminating air gaps and potential defects within the concrete mix.

Types and Applications

The versatility of concrete compaction equipment is evident in the variety of models available. Internal vibrators, with their long tubes and vibrating heads, are ideal for direct contact applications, ensuring thorough compaction from within. External vibrators, or form vibrators, are used when internal methods are impractical, although they may lead to some energy loss. Surface vibrators are best suited for shallower depths, effective up to 20 cm. For industrial applications, vibrating tables are employed to compact stiff mixtures in factories and laboratories, utilizing electric motors for efficient operation.

Features and Design

A concrete vibrating table is typically constructed from durable metals and is attached to steel springs, allowing for robust and consistent vibrations across the table's surface. The design incorporates an electric motor that drives the vibrations, which are critical in settling the concrete mix into a dense and uniform composition. This design is pivotal in preventing defects such as bug holes and honeycombing, which can compromise the structural integrity of the final product.

Materials and Advantages

The materials used in the construction of a vibration table for concrete molds are selected for their durability and performance. The advantages of using such tables are manifold, including the assurance of a defect-free concrete surface, the prevention of structural weaknesses, and the enhancement of the concrete's aesthetic finish. By ensuring a homogenous concrete mix, these tables contribute to the safety and durability of the constructed edifice, making them indispensable in the face of natural calamities and everyday wear.

Selection Considerations

When selecting a concrete vibrator table, it is important to consider the specific requirements of the project, such as the intensity of the concrete mix and the depth of the concrete surface. The choice between electric and gas-powered vibrators will also depend on the intended use and the availability of power sources. It is essential to select a table that aligns with the specific needs of the task at hand to ensure optimal compaction and surface quality.

Industry Applications

Concrete vibration equipment finds its applications across a broad spectrum of industries, from transportation infrastructure to residential construction, and even in laboratory settings where precision and reliability are paramount. The role of these tables in creating smooth, gap-free surfaces makes them a key component in the pursuit of quality and excellence in construction and manufacturing processes.