Popular in your industry

Related Searches:

Top categories

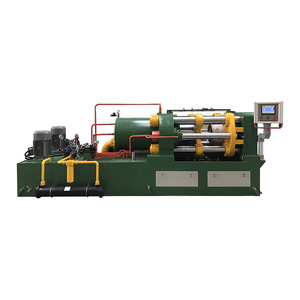

About continuous extrusion line for copper

Introduction to Continuous Extrusion Lines for Copper

The continuous extrusion line for copper represents a sophisticated category of equipment in the field of metal and metallurgy machinery. This machinery is pivotal in the production of copper and its alloys, serving as a backbone for various industrial applications. The continuous extrusion process is a method of manufacturing that involves the seamless transformation of copper billets into a variety of finished products without interruption.

Types and Applications

There are several types of continuous extrusion lines, each designed to meet specific industry needs. These include lines for flat wire, multiport tubes, and other complex profiles. The applications of these lines are extensive, ranging from electrical components, such as wires and cables, to architectural structures and automotive parts. The versatility of these machines allows for a broad spectrum of uses in manufacturing plants and building material shops.

Technical Features

A continuous extrusion line for copper is equipped with advanced features that ensure efficiency and precision. These lines typically come with fully automatic control systems, hydraulic presses, and balers. The technical specifications may vary, but a common voltage for operation is 380v. The machinery's design focuses on continuous production capabilities, which is essential for meeting the demands of large-scale industrial output.

Material and Construction

The construction of a continuous copper extrusion line involves robust materials capable of withstanding the rigors of metal processing. The durability of these machines is critical, as they must maintain performance under high temperatures and mechanical stress. The materials used in the construction of these lines are selected for their strength and resistance to wear, ensuring longevity and reliability.

Advantages of Continuous Extrusion

The advantages of using a continuous extrusion line are manifold. These lines offer an uninterrupted production process, which translates to higher productivity and reduced material waste. The continuous nature of the process also ensures consistent product quality, with less downtime for maintenance or setup changes. Furthermore, the automation integrated into these lines reduces the need for manual intervention, enhancing operational safety and precision.

Support and Technical Assistance

While exploring options for a continuous extrusion line for copper, potential users can expect to find various support services available through suppliers. These services may include online support, video technical support, and the availability of engineers for machinery servicing. Such support ensures that the machinery operates at peak performance and that any issues can be promptly addressed.