Popular in your industry

Related Searches:

Top categories

About cricket bat mould

Exploring the Versatility of Cricket Bat Moulds

The realm of cricket equipment manufacturing is incomplete without the mention of cricket bat moulds. These specialized moulds are pivotal in crafting the quintessential cricket bat, a central tool for the sport loved by millions. Cricket bat moulds are not just about shaping the bat but also ensuring consistency, precision, and adherence to international cricket standards.

Understanding Cricket Bat Mould Types and Materials

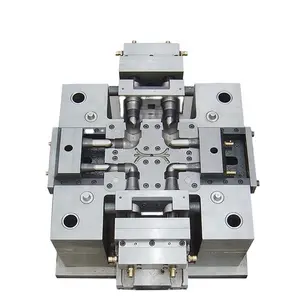

Cricket bat moulds come in various types, each designed to meet different production needs. From simple wooden moulds for traditional bat shaping to advanced composite materials for mass production, the choice of mould depends on the desired outcome and manufacturing capabilities. Materials used in these moulds range from hardened steel for longevity to aluminum and plastic for cost-efficiency and lightweight properties.

Applications and Features of Cricket Bat Moulds

The application of cricket bat moulds extends beyond just forming the bat's shape. They are instrumental in creating bats with specific weight distribution, balance, and handle alignment. Features such as non-stick coatings and temperature resistance are also integral, allowing for seamless bat removal and durability during the manufacturing process.

Advantages of Using Quality Cricket Bat Moulds

Employing top-grade cricket bat moulds brings forth several advantages. They ensure uniformity in bat production, essential for both amateur and professional levels of cricket. Moreover, the use of robust moulds minimizes material wastage and enhances the efficiency of the bat-making process. This efficiency is crucial for suppliers aiming to meet the high demands of cricket enthusiasts worldwide.

Selection Criteria for Cricket Bat Moulds

When selecting a cricket bat mould, manufacturers consider factors such as mould longevity, ease of use, and the ability to produce bats that meet regulatory size and weight specifications. The choice of mould also depends on the type of wood being shaped, as different woods may require different mould features to accommodate their unique properties.

Environmental Impact and Sustainability

In today's eco-conscious market, the environmental impact of cricket bat production is also a consideration. Sustainable cricket bat moulds are designed to reduce waste and are made from recyclable materials, contributing to a greener manufacturing process. This sustainability aspect is increasingly becoming a deciding factor for businesses in the cricket equipment industry.

Incorporating these insights into the selection and use of cricket bat moulds can significantly impact the quality and performance of the final product. While Alibaba.com serves as a bridge connecting suppliers with potential buyers, it is the meticulous craftsmanship facilitated by these moulds that ultimately defines the excellence of cricket bats on the field.