Exploring Custom Blue Film Varieties

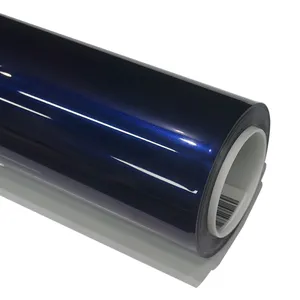

The term custom blue film encompasses a diverse range of polymer-based materials designed to cater to various protective and aesthetic needs in multiple industries. Predominantly utilized in the realm of plastics, these films are engineered to offer specific functional properties such as scratch resistance, UV protection, and resistance to abrasion, aligning with the unique requirements of each application.

Types and Applications of Blue Films

Custom blue films are segmented into several types, including plastic films used for packaging, car films for automotive protection, and decorative films for interior design purposes. Each category serves a distinct function, from safeguarding goods during transit to enhancing the visual appeal of vehicle exteriors or interior spaces. The adaptability of these films allows for their use in a multitude of settings, ranging from commercial packaging solutions to the customization of personal vehicles.

Features and Material Specifications

The features of custom blue film products are as varied as their applications. Key characteristics such as anti-scratch capabilities ensure longevity and maintain the pristine condition of surfaces. UV proofing is another critical feature, providing a shield against the harmful effects of the sun's rays, while sand proof qualities prevent surface abrasion caused by particulate matter. The materials used in the production of these films include polyethylene, polypropylene, and PVC, each selected for their durability, flexibility, and adaptability to different environmental conditions.

Advantages of Using Custom Blue Films

Employing custom blue film offers a plethora of advantages. These films are tailored to protect against specific elements, thereby extending the life of the products they cover. Their customizability allows for a perfect fit for any application, ensuring comprehensive protection. Moreover, the films' ease of application and removal streamlines the process, making them a convenient option for both temporary and long-term use.

Environmental Impact and Sustainability

In today's eco-conscious market, the environmental impact of custom blue film is a significant consideration. Manufacturers are increasingly adopting sustainable practices, utilizing recyclable materials, and reducing waste in the production of these films. This shift not only addresses environmental concerns but also meets the growing demand for sustainable product options.

Choosing the Right Custom Blue Film

Selecting the appropriate custom blue film requires an understanding of the specific needs of the application. Factors such as the level of protection needed, exposure to elements, and the duration of use play a crucial role in determining the most suitable film type. It is essential to consider these variables to ensure optimal performance and protection.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4