A DIY conveyor belt is a customized and homemade conveyor system designed for small-scale material handling projects. Enthusiasts often create these systems for applications such as moving items in workshops, gardening, or even as part of a DIY production line. The advantages of a homemade conveyor belt lie in its cost-effectiveness, customization options, and suitability for small-scale applications. Enthusiasts can tailor the system to meet specific requirements, and the DIY approach often allows for a more affordable solution compared to commercial conveyor systems.

Types of DIY conveyor belts

Comparing DIY conveyor belts involves evaluating the complexity of the design, materials and features incorporated. Some DIY enthusiasts may opt for a straightforward system with manual operation, while others might integrate motors, sensors, or additional controls for automation. The choice depends on the specific requirements of the application. For instance, specific requirements could involve moving materials in a workshop, transporting soil or other substances in gardening projects, or even creating a simple production line for DIY manufacturing.

A DIY conveyor belt is versatile and finds applications in various scenarios. It is commonly used in small workshops for material transport, in gardening setups for soil or plants, or even as part of a hobbyist's DIY project. The adaptability of these systems allows for customization to suit different needs. In contrast, a DIY conveyor system can range from a simple setup using rollers and a belt to more intricate designs involving motors, sensors, and controls. Additionally, a DIY conveyor belt for dirt may have specific features like increased durability and resistance to soil and debris. A mini DIY conveyor belt is a smaller version suitable for lighter loads or limited space.

Materials and features of DIY conveyor belts

Using a DIY conveyor belt involves assembling the components to create a functional system. Rollers, a belt, and a frame are essential parts of the assembly. Choose materials based on the weight and type of materials the conveyor will handle. When selecting materials, consider factors like durability, flexibility, and ease of maintenance.

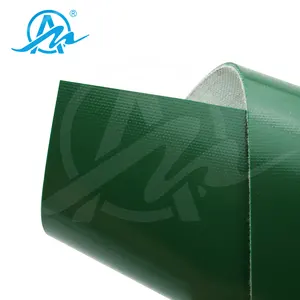

Common materials include rubber for the belt, sturdy fabric, or even modular plastic components for the conveyor surface. The frame is often made from metal or wood, and rollers can be crafted from materials like PVC or metal. Materials for a DIY conveyor belt can vary based on the project's requirements. For instance, a DIY conveyor belt for dirt requires materials that are durable and resistant to soil and debris. A reinforced rubber belt and metal or PVC rollers are commonly used to ensure longevity in such applications. In contrast, to create a robust DIY conveyor belt for heavy-duty applications, it is recommended to select durable materials such as a reinforced rubber belt, sturdy metal frame, and heavy-duty rollers. The weight and type of materials the conveyor will handle should be kept in mind when selecting a DIY conveyor belt.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4