Introduction to Electrical Cooker Molds

The realm of manufacturing electrical cookers involves precision and customization, where electrical cooker molds play a pivotal role. These molds are the foundational tools used to shape and solidify the components of electrical cookers, ensuring consistency and functionality in the final product. The category encompasses a variety of molds tailored to different parts and specifications of electrical cookers.

Types and Applications

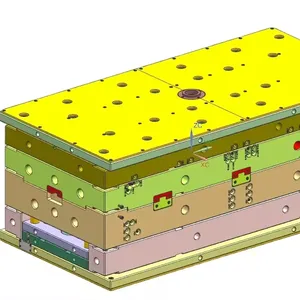

Electrical cooker molds come in diverse types, each serving a specific purpose in the production process. From injection molds designed for intricate, functional parts to larger molds for aesthetic components like decorative plating, the applications are extensive. These molds are not one-size-fits-all; they are crafted to meet the unique requirements of each electrical cooker design.

Material Selection and Features

Selecting the appropriate material for an electrical cooker mold is crucial. Options range from robust iron to advanced composites, each offering distinct advantages in durability and mold longevity. Features of these molds can be highly specialized, including heat resistance and precision surface finishes, which are essential for the efficient production of electrical cooker components.

Advantages of Standardization

Optimizing production is a key benefit of standardizing certain elements of electrical cooker molds. By harmonizing features such as lift bars, connection sizes, and clamp slots, manufacturers can streamline the molding process across various products. This approach not only simplifies the manufacturing workflow but also potentially reduces costs associated with mold production.

Ensuring Mold Accuracy

Accuracy in mold design is paramount, and professionals in the field work meticulously to refine electrical cooker molds until they meet the precise specifications. This often involves creating multiple test samples to ensure that the mold performs as intended, resulting in consistent and reliable parts for electrical cookers.

Finding the Right Mold on Alibaba.com

Alibaba.com serves as a conduit, connecting businesses with a plethora of suppliers offering various electrical cooker molds. The platform facilitates the discovery of suitable molds that align with specific manufacturing needs. By leveraging the detailed information provided by suppliers, businesses can make informed decisions to fulfill their requirements for electrical cooker mold production.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4