(973 products available)

Market Overview: The global market for electrical discharge machines, including electro erosion machines, was valued at approximately $6.6 billion in 2023 and is projected to grow to $9.4 billion by 2030, reflecting a compound annual growth rate (CAGR) of 5.3% during this period, according to Global Industry Analysts, Inc. This growth is primarily driven by the increasing demand for precision machining in various industries such as aerospace, automotive, and electronics. Notably, the Wire Cutting EDM segment is anticipated to reach $5.7 billion by 2030, growing at a CAGR of 5.8%, indicating a strong preference for this technology among manufacturers. Regionally, the U.S. market was estimated at $1.8 billion in 2023, while China is expected to grow at an impressive 8.8% CAGR, reaching $2.1 billion by 2030, showcasing the importance of these markets in the global landscape.

Industry Insights: Shifts in consumer behavior indicate a growing emphasis on automation and efficiency in manufacturing processes. The rising complexity of components, especially in high-tech industries, necessitates the use of advanced electro erosion machines for intricate tasks. Furthermore, as companies strive for sustainability, there is a noticeable shift toward machines that minimize waste and energy consumption. The adoption of these machines is also influenced by the ongoing trend of digitalization in manufacturing, enhancing operational efficiency. Additionally, the market faces challenges such as high initial investment costs and the need for skilled labor to operate these sophisticated machines. However, the ongoing advancements in technology and the expansion of applications in niche markets present significant opportunities for growth in the electro erosion machine sector.

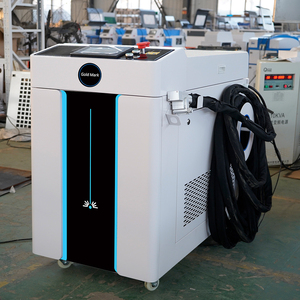

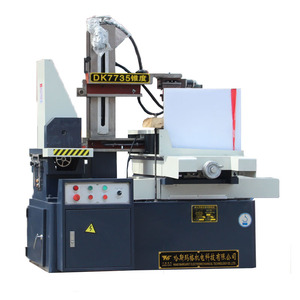

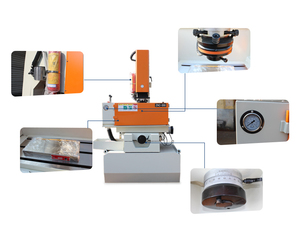

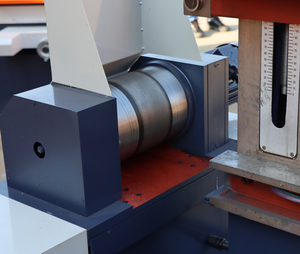

Electro Erosion Machines are two basic types: wire EDM and spark EDM. Also, there are some variations on the machines.

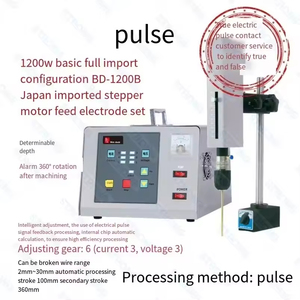

Additionally, adjusting or splitting electrodes is called EDM dressing. They can be made in various shapes to suit specific machining needs.

Wire electrical discharge machining (EDM) machines also come in different forms, such as:

Some specifications for the electro erosion machine include the following:

Machine maintenance:

Due to its adaptability, the EDM machine is employed in various industrial sectors.

Tool and Die Making:

The core and cavitate of injection molds, blow molds, and plastic mold making utilize erosion machines. EDM creates precise and complex shapes and features, including undercuts, internal cavitation, and thin walls. Additionally, it has designed and produced punches, dies, forming tools, and stamping components with intricate contours and profiles.

Aerospace and Automotive:

EDM machines play a vital role in the aerospace and automotive industries. They are used to manufacture high-precision components for aerospace engines, such as turbine blades, injector nozzles, and blade slots. Additionally, the machines cut complex lightweight structures for the aerospace industry and automotive industry to produce prototyping assembly jigs, fixtures, and quality instruments. EDM machines can produce high-precision parts such as gear sets, valves, pumps, and instrument components.

Medical Device Manufacturing:

Electro-erosion machines create high-precision medical devices and instruments such as surgical instruments, implants, catheters, and stents. These include components with delicate details, including slots, apertures, and internal channels. EDM machines make minimally invasive surgical devices likewise. In addition, EDM machines increase biocompatibility and reduce surface roughness of medical devices by making micro-engraving and marking on the surface of medical instruments.

Electronics Industry:

The electronics industry relies on electro-erosion machines for various applications. These machines are used to cut intricate patterns, traces, and openings on printed circuit boards (PCBs). Additionally, EDM machines create microscale components such as connectors, sockets, and microelectronic devices in the electronics industry. The machines are capable of engraving logos, serial numbers, barcodes, and other identifying marks on electronic device surfaces rapidly and accurately.

Firearms Manufacturing:

The firearms industry employs wire erosion machines to manufacture firearm components such as barrels, receivers, slides, and frames. The machines are capable of machining complex and precision shapes and also enhance the firearm components' quality and accuracy.

Optics and Electronics Industry:

For precision optical components such as lenses, mirrors, and apertures, as well as microelectronics devices, connectors, and sockets, machining is used to achieve the required accuracy, reliability, and performance standards in electronic products.

Both the tooling companies and retail buyers need to consider various parameters when selecting the proper electro erosion machines for their applications.

Application Requirement Analysis:

Buyers should define the specific applications and material types to be used in the machining process. This may include the shapes and sizes of workpieces that need to be used. The buyer's machining requirements, such as accuracy, surface roughness, and processing speed need to be assessed as well. Buyers should match the types of machines with their needs. For instance, a rotary wire EDM machine would be better matched for a buyer with high-speed processing and precision requirements.

Machine Specifications Comparison:

Once the requirement analysis has been done, buyers should compare electro erosion machine specifications, including their power, control system, and electrode types among others. The working area and electrode types of a machine need to be compatible with the buyer's work requirements. For instance, a small machining area and wire electrode might not work well for a large metallic workpiece.

Also, the parameters of the machine for its cutting power need to be examined. Some machines might be set to give a rough cut initially which might be the case in selective machining scenarios whereas others would have a higher setting to give finer cuts only.

Space Requirement and Weight:

For the easy installation of the machine in a workshop space, its weight and overall dimensions should be known. Along with the machine's space requirement, the transportation and installation process should also be looked into before making a purchase.

After-Sales Support and Maintenance:

Consider the machine's maintenance and replacement part needs. Buyers should also look into the supplier's technical support, repair services, and availability of spare parts to ensure a hassle-free operation and to reduce downtime in critical situations.

Q1: What are some recent trends in the development of electro erosion machines?

A1: The recent trends in the development of electro erosion machines include increasing automation features like CNC controls, more compact table-sized models for machine shops, higher energy-efficient generators to reduce power consumption, and digital readouts for precision measuring and simplified operator controls.

Q2: How long an erosion machine can work continuously without overheating or needing a break?

A2: The EDM machine can run continuously for 24 hours a day, seven days a week for about two weeks before it needs a break and some routine maintenance. But it is better to stop the machine after about 12 to 14 hours of continuous operation so that the work wire can be changed and the cooling system can be checked.

Q3: What are some safety features to prevent accidents during electro erosion machining?

A3: The erosion machine has some safety features that buyers will find, such as emergency stop buttons, interlocked access doors, coolant leak detectors, and voltage insulation precautions. Also, the operator should be properly trained to take all necessary safety precautions before using the erosion machine.

Q4: Can an electro erosion machine cut materials other than metal?

A4: An erosion machine cannot cut materials other than metal. This is because the machining process relies on the material's electrical conductivity to establish an arc and perform the cutting action. Metals like steel, titanium, copper, aluminum, brass, etc., possess the necessary conductivity. Nevertheless, some EDM machines can cut hard ceramics, composite materials, carbides, and geometries with metallic layers.