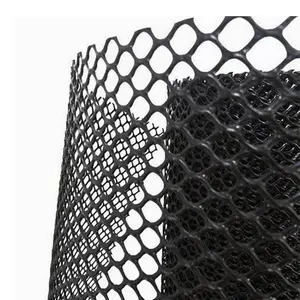

Introduction to Honeycomb Mesh Plastic

Honeycomb mesh plastic is an innovative material celebrated for its lightweight yet robust properties. This unique structure resembles a honeycomb, providing excellent strength and durability while maintaining a low weight. Commonly used across various industries, honeycomb mesh plastic finds applications in packaging, construction, automotive, and even aerospace sectors, making it a versatile choice for numerous projects. Its unique geometries allow for optimal space utilization without compromising performance, positioning honeycomb mesh plastic as a favored material for modern solutions.

Types of Honeycomb Mesh Plastic

Honeycomb mesh plastic is available in multiple types, each catering to distinct applications and preferences. Here are some common variations:

- Polypropylene Honeycomb Mesh: Known for its excellent chemical resistance and recyclability.

- Polyethylene Honeycomb Mesh: Offers outstanding impact resistance and is ideal for outdoor use.

- ABS Honeycomb Mesh: Provides superior strength and is often used in automotive applications due to its toughness.

- Aluminum Honeycomb Mesh: Lightweight and incredibly strong, making it ideal for aerospace and high-performance applications.

Applications of Honeycomb Mesh Plastic

The versatility of honeycomb mesh plastic lends itself to a wide range of applications. Here are some notable uses:

- Packaging: Protects fragile items during transit, reducing breakage and ensuring safety.

- Construction: Used in lightweight panels that contribute to energy efficiency while minimizing weight.

- Automotive: Utilized in vehicle interiors and structural components for weight reduction and fuel efficiency.

- Aerospace: Incorporated in aircraft structures, providing strength without adding excessive weight.

- Interior Design: A contemporary choice for decorative wall panels and furnishings.

Features and Advantages of Honeycomb Mesh Plastic

The features of honeycomb mesh plastic contribute extensively to its popularity. Here are key attributes that make it a preferred material:

- Lightweight: Its honeycomb structure ensures that the material remains light while retaining strength.

- High Strength-to-Weight Ratio: Balances high durability and minimal weight, making it ideal for demanding applications.

- Thermal Insulation: Acts as an efficient insulator, aiding in temperature regulation.

- Moisture Resistance: Resists environmental moisture, enhancing longevity and usability.

- Eco-Friendly: Made from recyclable materials, making it a sustainable choice for the planet.

- Customizable: Can be easily molded to various shapes and sizes, catering to specific project requirements.