Popular in your industry

Related Searches:

Top categories

About hydraulic press machine 40 ton

The 40-ton press machine is designed to deliver substantial pressure, making it suitable for various applications in manufacturing and metalworking. A 40-ton hydraulic press is a machine tool that uses hydraulic pressure to compress materials. The machine consists of a hydraulic system, a bed, a ram, and a set of guiding columns. The hydraulic system generates the force needed for the pressing operation. The bed provides a stable platform for the workpiece, while the ram, driven by hydraulic cylinders, exerts the force on the material. The guiding columns ensure the precise alignment of the ram and the bed, allowing for accurate and repeatable pressing.

40 Ton Hydraulic Press Applications

The 40-ton hydraulic press machine is a versatile tool used in various industries for pressing, bending, straightening, and forming operations. The 40-ton press finds applications in metal fabrication, automotive, aerospace, and manufacturing industries. In metal fabrication, the 40-ton press is used for tasks such as punching, stamping, and deep drawing of sheet metal. The press's high force capability allows it to form complex shapes with high precision. In the automotive industry, the 40-ton hydraulic press is used in the production of components such as body panels, chassis parts, and engine components. The press is also used for assembly tasks like pressing bearings and bushings. In the aerospace industry, the 40-ton press is used for manufacturing critical components like aircraft skins, structural parts, and composite materials. The press's ability to exert precise and controlled force is crucial for ensuring the structural integrity of aerospace components. In the manufacturing industry, the 40-ton press finds applications in various processes such as forming, blanking, and shearing of materials. The press is also used for tasks like assembling components and pressing bearings. The 40-ton hydraulic press is a powerful and versatile machine tool that finds applications in various industries for performing a wide range of pressing and forming operations. Its ability to generate high force and precise control makes it an indispensable tool for tasks that require accuracy and reliability.

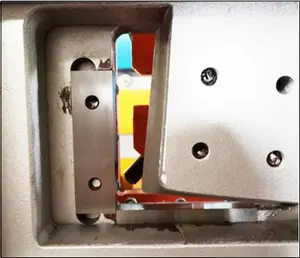

40 Ton Hydraulic Press Components

The key components of a 40-ton hydraulic press machine include the hydraulic system, the frame, the hydraulic cylinders, the ram, and the controls. The hydraulic system of the 40-ton press is the heart of the machine, responsible for generating and distributing the hydraulic force. It comprises a hydraulic pump, valves, hoses, and a hydraulic fluid reservoir. The hydraulic pump pressurizes the hydraulic fluid, which is then controlled by valves to actuate the hydraulic cylinders. The frame provides the structural support for the press and houses the hydraulic components. It is typically made of robust materials like steel to withstand the forces generated during pressing operations. The hydraulic cylinders are the actuators that convert hydraulic pressure into linear force. In a 40-ton press, these cylinders are designed to provide a maximum force of 40 tons. The ram, attached to the hydraulic cylinders, is the part of the press that directly applies the force to the workpiece. It moves up and down in a controlled manner to perform pressing operations. The controls of the press allow the operator to manage the press's functions. They include features like pressure adjustment, speed control, and safety mechanisms. The controls may be manual, semi-automatic, or fully automated, depending on the press's design. The 40-ton hydraulic press machine is a robust and well-engineered piece of equipment that integrates various components to deliver precise and powerful pressing capabilities. Its hydraulic system, frame, cylinders, ram, and controls work in harmony to provide the force and control necessary for a wide range of industrial applications.