(3755 products available)

Ready to Ship

Ready to Ship

Cutting leather for plotters is a very fine art that requires skill and attention to detail. They are classified into two types based on their functionality and work criteria. These are the drag knife plotters and the tactile plotter cutters.

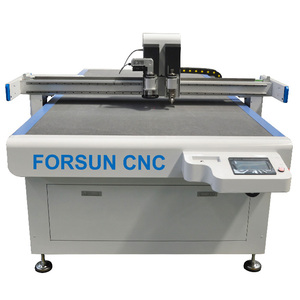

Generally speaking, the specifications of leather cutting plotters vary according to their models and types. They are generally equipped with cutting heads, entire areas, control systems, and software.

Among them, cutting heads are the key components of leather cutting plotters, which are responsible for cutting leather materials. Usually, the cutting heads of leather cutting plotters come in more than one size and shape to accommodate different cutting requirements. For instance, fine-point blades are used for precision cutting, while curved blades are used for cutting curves and irregular shapes. The blade material is usually stainless steel or other alloy materials, which are sturdy and durable.

The entire area refers to the working surface of the leather cutting plotter. It is also the area where materials are laid out and cut. The size of the entire area corresponds with that of the material. For example, the usable area of a small-scale leather cutting plotter may be merely 600x300mm, while that of a large-scale plotter with a wider cutting area may reach up to more than 1,600x1,200mm.

Leather cutting plotters are also equipped with some auxiliary components to improve cutting efficiency and accuracy, such as vacuum systems and claw devices. The vacuum system usually fixes the material to be cut on the working surface through a suction process to ensure stability and immobility during the cutting process. Meanwhile, the working surface of leather cutting plotters is mostly made of PVC and feature a peculiar hole-pore design. This design allows for sufficient air circulation and absorbs the material to be cut, providing great support for the bottom of the leather material. On the other hand, paw devices manipulate and position the cutting materials by grasping them through mechanical claws.

The control system is the brain of the leather cutting plotter. It integrates the machine's internal circuits and controls, enabling it to receive cutting instructions and realize automatic cutting operations. The control system usually adopts an embedded design, equipped with a microprocessor and control modules.

In addition, the leather cutting plotter is often compatible with CAD/CAM software to facilitate users' design and modification of cutting programs. These software packages usually provide intuitive design interfaces and powerful design tools to meet users' various design needs. The software is user-friendly and usually allows users to import different file formats, including images, vector graphics, etc. Users can then edit the graphics, set cutting parameters, and generate cutting programs to control the leather cutting plotter.

Maintaining a leather cutting plotter is essential to its longevity and performance. Regularly cleaning the plotter is an integral part of the maintenance process. It prevents dust, debris, and leather particles from accumulating and obstructing the cutting blades or sensors. It is critical to follow the manufacturer's guidelines carefully for cleaning, ensuring the right products and techniques are used. Lubricating moving parts such as tracks and gears helps reduce friction and ensures smooth movement, thereby prolonging the life of the plotter. Oil or lubricant specifically formulated for cutting plotters should be used for the best results. Regularly inspecting and calibrating the cutting blade is equally important, as this helps to ensure the cutting precision of the plotter. Users should check for signs of dullness or damage to the blades and replace them as needed. Calibration of the blade's position and sensitivity may also be necessary to maintain accurate cutting.

The following industries use a leather cutting plotter with varying use cases.

Apparel industry

The apparel industry is one of the biggest users of leather cutting plotters. They use this machine to cut all sorts of leather pieces for clothing items such as jackets, pants, skirts, vests, coats, and more. Additionally, the leather cutting plotter is used to make leather accessories that go with outfits—examples like belts, caps, patches, and just about anything that requires leather to glamorize an outfit.

Automotive industry

The automotive/automobile industry requires leather pieces for car interiors such as seats, dashboards, door panels, steering wheels, etc. Automobile luxury cars are more likely to have leather components.

Furniture industry

The furniture industry employs graphtec leather cutting plotters to mold and shape leather pieces for plush furniture like stylish sofas and elegant chairs. Leather is a sturdy, long-lasting material that can withstand the abuse of frequent use.

Handicraft and Accessories Industry

Creative businesses and independent artisans frequently use leather cutting plotters to precisely cut leather for unique items like wallets, handbags, belts, jewelry, phone cases, and more.

When in need of a large leather cutting plotter for sale, it is essential to look for the most popular models among buyers in the target market. Focusing on customers' needs is a surefire way of selecting the right kind of machine to sell.

The first thing to consider when choosing a leather cutting plotter is the type of machine and what it offers. Check if the item is a manual, automatic, or semi-automatic item and how it works. Investigate how distinct types of machines handle various materials. For example, an automatic leather cutting plotter can easily handle materials with high productivity needs and varying shapes and sizes.

Next, study the features of the cutting plotter. It includes the table size, cutting thickness, cutting method, and precision. In general, a plotter with a bigger cutting area will handle larger work pieces more easily. Increased cutting thickness enables the machine to cut a wider range of materials. An increase in cutting accuracy will result in cleaner edges and more precise cuts.

Find out how easy it is to operate a leather cutting plotter cutter. Determine whether it comes with cutting software and what kind of learning curve is involved. Also, look at the precision and speed at which it works. In the leather and garment industry, time is money. Therefore, selecting the type of plotter that works fast and with high accuracy can improve product yield.

Consider the after-sales support the suppliers offer. Choose those with easy-to-reach customer care support. Apart from fast delivery and flexible return policies, the customer care should be supportive and knowledgeable about the product. This kind of support will help sellers and buyers go through the buying and selling process comfortably.

Q1: What is the difference between a leather cutting plotter and a laser cutter?

A1: A leather cutting plotter uses blades to cut materials, while laser cutters employ beams of light to cut through various types of material. Laser cutters can offer more precise cuts, especially for intricate designs. However, they are also more expensive in terms of both machines and maintenance.

Q2: Can a plotter cut thick leather?

A2: Leather cutting Plotters can cut thick leather, but the thickness they can handle depends on the machine's specifications. It's essential to find a plotter that can cut thick leather if that's a particular requirement.

Q3: Are leather cutting Plotters easy to use?

A3: Most Cutting plotters are easy to use. Most of them come with software that helps users create designs and tell the machine what to cut. However, like any other machine, there's a learning curve.

Q4: Can a leather Cutting Plotter Machine cut materials other than leather?

A4: Yes, many leather cutting plotters can cut various materials, including paper, vinyl, fabric, and cardstock. However, it's essential to check the machine's specifications and capabilities before trying to cut a new material.