Market Dynamics for Machinery to Make Nails

Market Overview: The market for machinery to make nails is poised for notable growth, reflecting broader trends within the metalworking machinery sector. According to 360iResearch™, the Knuckle Joint Press Machine Market, which is integral to nail production, expanded from USD 2.93 billion in 2023 to USD 3.09 billion in 2024, and is projected to grow at a CAGR of 5.72%, reaching USD 4.33 billion by 2030. This growth underscores the increasing demand for efficient manufacturing processes in the nail production industry, driven by rising construction and manufacturing activities globally. Additionally, the global market for metal sawing machines, essential for precision work in nail manufacturing, is expected to grow from USD 3.4 billion in 2023 to USD 4.1 billion by 2030, further emphasizing the machinery's importance in this niche sector.

Industry Insights: The machinery to make nails benefits from a diverse set of market drivers, including the ongoing expansion of the construction industry and the rise in consumer demand for nail products. With the U.S. nail care market estimated at USD 10.7 billion in 2023 and projected to reach USD 12.8 billion by 2030, the demand for efficient manufacturing solutions is critical. Emerging trends such as sustainability and automation are influencing machinery preferences, with manufacturers seeking equipment that minimizes waste and boosts productivity. Furthermore, the integration of advanced technology in machinery, such as automated controls and smart manufacturing capabilities, is reshaping production lines. As consumer preferences shift toward high-quality and diverse nail products, machinery producers must adapt to meet these evolving demands, ensuring their offerings align with market expectations.

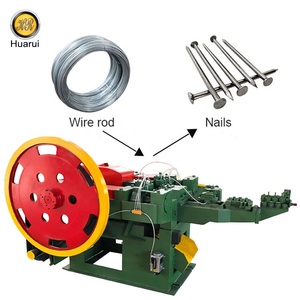

Types of machinery to make nails

A nail-making machine turns raw materials into completed products through a series of manufacturing processes. Different types of machinery exist that can make nails.

-

Automatic nail-making machine

This machine produces nails at a high volume for large-scale supply. It generally features a multi-station forming mechanism, programmable controls for nail size and length variations, and high-speed feeding and cutting systems. The multi-station forming mechanism twists and flattens the wire, creating the nail-shaped structures within the machine. Notable configurations are nail-making machines with and without an integrated nail head formation feature. The incorporated head-forming feature may reduce the need for additional processing steps to complete the nails, expediting the workflow for manufacturers.

-

Manua

Manual nail-making machines are generally used to produce specialized nails or work in remote areas without electricity. Operators feed wire through the machine, cut it to length, and bend it into shape using a combination of hand tools and the machine.

-

Hydraulic nail-making machine

A hydraulic nail-making machine often uses hydraulic power to form nails from wire, which is commonly used when materials of varying thicknesses and sizes are involved. This machine may require operator assistance to load the wire or manually engage the hydraulic system to cut and shape the wire into nails.

-

Pneumatic nail-making machine

A pneumatic nail-making machine, as implied by the name, uses compressed air to form nails. This type is not as common as the hydraulic nail-making machine. It may integrate with assembly lines to produce specific types of nails for construction or other industries. The nail is often fed into a nail gun or other fastening tool, streamlining the manufacturing and supply process.

-

Combined nail-making and nail polishing machine

This machine combines the nail-making and polishing processes in a single device. It has the advantage of reducing production line fragmentation and facilitating the flow of products through the manufacturing process at a more rapid rate.

-

Custom nail-making machine

Some manufacturers may consider purchasing a custom nail-making machine to suit their specific production requirements.

Specifications and maintenance of machinery to make nails

Specifications

Details like specification and maintenance requirements may vary depending on the exact nail-making machinery. Hence, the details above may not apply to all types of nail-making machines.

Maintenance

General maintenance requirements for nail-making machinery are as follows:

- Ensure all parts and components are free of dust and debris to improve the performance and efficiency of the nail-making machines. Use air compressors or vacuum cleaners to remove particles that are otherwise difficult to reach by hand, particularly in tight spaces.

- Lubricate moving parts, including rollers, chains, and bearings, to facilitate smooth operations, minimize wear, and reduce noise. Apply lubricant to them using an oil can or a cloth.

- For electric nail-making machines, check the power cords and plugs to ensure they are in good condition and not damaged to prevent potential electrical hazards. To keep electrical connections intact, ensure there is no corrosion, loose connection, or degradation over time.

- Relieve tension on the blades and cutters after using the machines, as this helps prevent them from becoming deformed over time, thus maintaining their cutting precision.

- Document the maintenance history of the nail-making machine, which includes, but is not limited to, the replacement of any parts, repairs, and adjustments made. Also, ensure the machine is operated according to the manufacturer's guidelines and suggestions to prevent damage.

Usage scenarios of nail-making machinery

The general usage scenarios of the machinery to make nails are as follows.

- Construction: The construction industry is the largest market for nails. No matter what kind of building, various types of nails are used. Therefore, commercial buyers of nail-making machines are mainly found in the construction industry.

- Furniture industry: The furniture industry includes more than just manufacturers who make and sell their own furniture. Department stores, hotels, and other commercial clients are all looking for customized furniture. Many of them need to use customized commercial-grade furniture that is stronger than regular home furniture, which involves more expensive, higher-quality machines that can make more substantial, longer nails.

- Hardware product manufacturing: This includes not only the tools and hardware used in the construction industry but also things like artificial flowers and jewelry. The artificial flower market is significant. Artificial flowers often use complex inner and outer layers of FYEs. The jewelry includes diamond and other precious stone jewelry that needs to use high-quality solid nails to help the jewelry stay together.

- Shops that sell nail-making machines: Shops that sell nail-making machines are a target market for machines that make nails. Unlike a hardware store, which sells products directly to consumers, nail-making machine retailers primarily sell to other retailers who resell nail products. Retail hardware stores are typically small businesses that serve individual homeowners and small contractors. Contemporary small hardware stores sell a large number of nails but cannot justify the purchase of a nail-making machine due to the scale of their business. A retail nail-making machine shop is likely to be larger in scale and have more commercial clients rather than small individual clients.

- Exporting countries' borders: The borders of countries that export are a market for nail-making machines. Countries that export goods are more likely to need nail-making machines than countries that do not, as the export market is limited to goods that require more complex, diversified, and greater quantities of nails. In many countries that are net exporters, the lack of machines means that the products in the export market cannot be exported.

- DIY market: The DIY market does not require extensive machinery to make nails. Many people can use lightly applied machinery that fits in their garages rather than industrial-strength production lines because the DIY market is relatively small compared to the total market for nails. The DIY market includes homeowners who do remodeling and new construction projects where their own skills may need to be improved, and they are looking for ways to save costs by making their own projects instead of hiring someone else to do them for them.

How to choose machinery to make nails

When buying nail-making machines for business, it is essential to check technical features and specifications to match production needs. Things like the raw materials used in the nail-making machine, the prevalent voltages and frequencies of machines, and installation and maintenance requirements should also be well thought out before purchasing.

- Compatibility with materials: The nail-making machine to buy will depend on the specific type of nail it aims to produce. However, all will require metal wires as raw material. But metal wires come in different grades and coatings. Therefore, ensure that the machine chosen can efficiently process the metal wire chosen as the material.

- Voltage and frequency compatibility: The voltage and frequency of the machinery are also essential for smooth operations in businesses. The prevalent voltage in North America is different from that in Europe and other parts of the world. In addition, developing countries that use electricity may have different transmission systems. Therefore, it is crucial to get a nail-making machine with the proper voltage and frequency for the area of operation to ensure adequate power transmission.

- Installation and maintenance requirements: The installation process of complicated industrial machines requires highly skilled technicians. To avoid incurring extra costs from expert installers, get nail-making devices that are easy to install and move into position at the production facility. In addition, maintenance is critical to ensure that the equipment continues to run smoothly for many years. It helps to maintain the machinery's resale value. Before buying, get information on the maintenance needs of the machines. Also, ensure that the machines have spare parts readily available.

Q&A

Q: How does a nail-making machine work?

A nail-making machine works by feeding metal wire through various components that cut, shape, and point the wire into nail forms. Different parts of the machine perform specific tasks, like cutting the wire to the desired length, forming the nail head, shaping the nail body, and creating the nail point.

Q: Is the nail-making machine automated or manual?

A nail-making machine is automated. It performs the entire process of making nails from wire through various steps, such as cutting, forming, pointing, and polishing, without manual intervention.

Q: What are the different types of nail-making machines?

The different types of nail-making machines include:

- Single-station nail-making machines.

- Rotary nail-making machines.

- Multi-station nail-making machines.

Q: What is the production capacity of a nail-making machine?

The production capacity of a nail-making machine varies according to the type and model of the machine and other factors like the size of the nails being made and the operator's efficiency. Generally, automated nail-making machines produce anywhere between 70 to 120 pieces per minute.

Q: What are the benefits of using a nail-making machine?

The benefits of a nail-making machine include:

- It can make different kinds of nails, such as common, concrete, framing, fin, pick, and others with special features.

- The machine can manufacture large volumes of nails in a short time.

- An automated nail-making machine reduces labor costs and boosts productivity compared to manual nail-making.

- The nails produced by the machine are more precise and consistent in size and shape, and this improves efficiency in application and ensures a good fitting.

- Nail-making machines are versatile, and they can use different types of metal wire to make nails with various coatings.

- A nail-producing machine can be integrated into existing manufacturing setups.