(13482 products available)

Ready to Ship

Ready to Ship

Ready to Ship

Ready to ShipSmall metal shredders are gathering popularity due to their ability to handle metal scrap efficiently while occupying less space. Many businesses now favor small shredders due to their practicality and cost-effectiveness. There are distinct types of metal shredders small, each designed for a specific application or material.

Rotary Shredder

A rotary shredder is a device that breaks down materials with the use of rotating drums. It is widely used in different industries to decrease the volume of materials. What makes a rotary shredder distinct from other shredders is its mechanism of using rotary discs or drums to break down materials. It offers an efficient method of shredding various types of materials including plastics, paper, and, in some models, metals.

Circular Shredder

An advanced metal shredder concept would involve a circular shredder. Such a shredder usually has a disc-shaped cutting mechanism. A circular shredder operates by using a circular movement to cut through materials. This enables the shredder to have multi-directional cutting abilities. Moreover, a circular shredder can be easily scaled from small to large depending on the intended applications.

Single-Shaft Shredder

Single shaft shredders are shredding devices with one rotor. The rotor features many unchangeable blades that cut and slice materials during the shredding process. Normally in a single shaft shredder, the blades have an angle which helps to cut different kind of materials precisely. Then the cut materials are usually streamed into a conveyor belt for further processing. Single shaft shredders are commonly used in recycling industries for plastics, wood and other materials. What makes them suitable for such materials is the efficiency and versatility of the shredder.

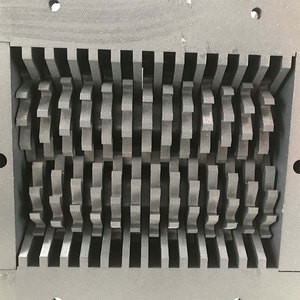

Twin-shaft Shredder

The twin-shaft shredder literally refers to a type of shredder with two shafts. It is also known as a double shaft shredder. The two shafts operate independently with interlocking blades. This ensures an efficient shredding and lacerating process for a wide variety of materials. Most commonly, a twin-shaft shredder can deal with tough materials such as plastic films, solid blocks and rubber. Nonetheless, it is crucial for one to know that a twin-shaft shredder was designed to take on more tough and robust materials, hence its heavy-duty capacity.

Low-horsepower metal shredders are efficient and have unique specs that make them ideal for small-scale shredding operations. Here are some of the critical specifications of small-scale shredders:

Maintaining a small-scale metal shredder improves its efficiency and prolongs its lifespan. Here are a few maintenance tips for small metal shredders:

The small metal shredder provides businesses with many usage scenarios. Firstly, in the manufacturing sector, the machine can reduce metal scraps, such as damaged parts or excess pieces during production. These can be fed into the shredder, which will produce smaller bits that are easy to manage or recycle. Additionally, industries that handle packaging waste can use small metal shredders to process. Used metal cans and containers can be fed into the shredder to create compact metal pieces for easier storage or recyclers' transportation.

Machine operators can easily feed the metal extras into the shredder, press a button, and let it shred. This saves time compared to traditional methods, which are labor-intensive. In the automotive industry, small metal shredders are used to process used automotive parts. Examples include salvaged metal components, such as brackets, frames, or engine parts. Shredding such parts helps reduce their storage space, makes it easier to extract valuable materials, and facilitates recycling.

Specialized metal shredders are used in the electronic industry to shred scrap metal from electronics. This includes metal housing, connectors, and circuit boards. Small metal shredders can handle low-power electronics. Once they are shredded, the various materials can be separated for recycling purposes.

Small metal shredders can be used to process biomedical metal waste. This includes metal instruments like scalpels, forceps, and syringes. Such instruments are not only used multiple times but also pose safety and health hazards. Shredding the biomedical waste makes it safer for disposal and can comply with regulations on healthcare waste management.

Metal shredders are also used in the construction industry to shred metal waste. Such wastes include rebar, metal roofing, and steel frames. Shredding the metal waste helps reduce the volume of waste that goes to landfills. It also aids the recycling process.

Smaller metal shredders can also be used in craft shops or DIY workshops. Here, hobbyists can shred used metal pieces to create space for upcoming projects or recycle responsibly.

Know the purpose of the shredder:

Before choosing a shredder, it's very important to know what one wants to use it for. Different small metal shredders are built to shred different types of metals. Knowing what type of metal it is for, as well as the intended use, will help one pick the most suitable shredder. For example, a person may want to shred old car parts or soda cans.

Consider the size and capacity:

Small metal shredders have different sizes and capacities. It's a good idea to think about how much metal one needs to shred and the space available for the shredder. Some small shredders can fit on a countertop while others are larger and need more floor space. Choose a shredder that is the right size for the job.

Check safety features:

Because shredders have fast-moving blades that can be dangerous, it's very important to consider the safety features of any small shredder before buying it. Look for things like safety interlocks, emergency stop buttons, and sturdy feeder chutes. Interlocks are mechanisms that prevent the shredder from operating if the access door is open. This prevents accidental shredding of hands or body parts. Safety chutes prevent users from putting their hands in the shredder inlet.

Evaluate noise levels:

It is an indisputable fact that shredders make noise. The level varies from one shredder to another. Before making a choice, it helps to consider how much noise one can take. Shredders with larger motors tend to be noisier. If one is concerned about disturbing others or the noise getting too much, one may want to choose a shredder with a lower noise rating.

Research brands and models:

Many brands and models of small metal shredders on the market have their own set of features. To choose the right shredder, take some time to research different brands and models. Read reviews from people who have bought and used the shredders already. This will help to know the limitations and strengths of each shredder. It will also help to know what others like and don't like about them. Armed with this information, it will be easier to make a smart purchase.

Q1: How powerful is a metal shredder small?

A1: The power of a small metal shredder can vary. It is typically measured in kilowatts (kW) or horsepower (HP). Specifications from different manufacturers indicate that shredders can have powers ranging from 3 kW to 22 kW.

Q2: Is a metal shredder small noisy?

A2: It can be. The shredder makes noise as it crushes metal. The level of noise depends on its design, the type of metal being shredded, and its power

Q3: Does a metal shredder small have dust and emissions?

A3: It can be. Shredding metal can produce dust and emissions. Therefore, any shredder should have an appropriate dust extraction system.

Q4: Which is better, a metal shredder small with a hydraulic or electric motor?

A4: An electric motor is more suitable for a metal shredder small with low power. Hydraulic motors are more powerful, dominating large machines. They also have higher shredding capacities.