Popular in your industry

Related Searches:

Top categories

About mini pcb cnc machine

Introducing Mini PCB CNC Machine

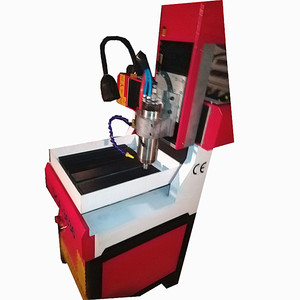

The mini PCB CNC machine is a compact computer numerical control (CNC) machine specifically designed for printed circuit board (PCB) manufacturing and prototyping. This versatile machine allows businesses to create intricate PCB designs with precision and efficiency. It is ideal for small-scale manufacturing, rapid prototyping, and educational purposes.

Technical Specifications

The mini PCB CNC machine typically features a working area of around 300mm x 180mm, making it suitable for handling small to medium-sized PCBs. It is equipped with a high-speed spindle motor capable of achieving precise cuts and engravings on various materials used in PCB production, such as FR4 and aluminum. The machine is often compatible with industry-standard software like GRBL for seamless operation.

Design and Features

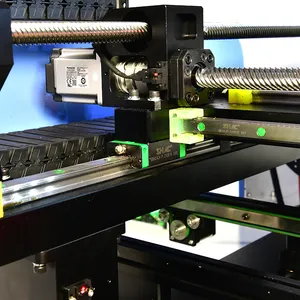

The mini PCB CNC machine is characterized by its sturdy frame and stable construction, ensuring vibration-free operation for intricate PCB designs. It is equipped with precision ball screws and linear guides that enable smooth and accurate movements during the manufacturing process. Additionally, some models come with automatic tool changers and dust collection systems for enhanced convenience.

Advantages of Mini PCB CNC Machine

One of the key advantages of the mini PCB CNC machine is its compact size, which makes it suitable for businesses with limited workspace. Its high precision and repeatability ensure consistent quality in PCB production, reducing material wastage and rework. Moreover, the machine offers versatility in creating complex PCB designs, including fine traces and intricate patterns.

Applications and Industries

The mini PCB CNC machine finds applications in various industries, including electronics manufacturing, aerospace, automotive, and telecommunications. It is used for producing prototype PCBs, small-batch production runs, and custom circuit designs. Educational institutions also benefit from these machines for teaching PCB design and manufacturing processes.

Choosing the Right Mini PCB CNC Machine

When selecting a mini PCB CNC machine, consider factors such as the machine's spindle speed, cutting accuracy, software compatibility, and technical support offered by the manufacturer. Look for machines that provide a user-friendly interface and efficient workflow to streamline your PCB production process. Additionally, assess the machine's scalability to meet your future manufacturing needs.

Maintenance and Care

To ensure optimal performance of your mini PCB CNC machine, regular maintenance is essential. Keep the machine clean from debris and dust accumulation, lubricate moving parts as recommended by the manufacturer, and calibrate the machine periodically for accurate cutting and engraving results. Proper maintenance not only extends the machine's lifespan but also maintains the quality of your PCBs.