Popular in your industry

Top categories

About nbk brakes

NBK brakes play an indispensable role in the automotive sector, providing vehicles with the requisite safety and performance standards. These systems are meticulously crafted to deliver dependable stopping capabilities, emphasizing longevity and operational efficiency. The term 'NBK brakes' covers an array of products, such as brake pads, shoes, and other pivotal components, all vital to the seamless operation of a vehicle's braking mechanism.

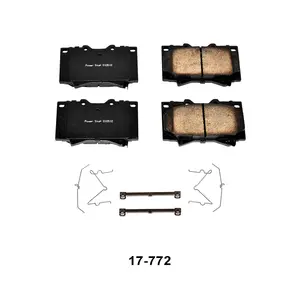

Types and Characteristics of NBK Brakes

Exploring the spectrum of NBK brakes, one encounters a diverse selection tailored to various vehicles and driving scenarios. For example, NBK brake pads Toyota are precision-made for Toyota models, guaranteeing an impeccable fit and superior function. The NBK LN508 FF and NBK D6272 FF brake pads serve distinct models, including the Land Cruiser and a range of Audi vehicles, respectively. Each variant of NBK brake pad or shoe possesses distinctive features, such as different hardness levels and friction coefficients, to meet the precise needs of the vehicle, whether for routine urban travel or more strenuous performance demands.

Structure and Operation of NBK Brake Systems

The intricate design of NBK brake systems is a testament to engineering prowess. A standard system comprises a brake pad, caliper, and rotor. The caliper functions as a vice, pressing the brake pads against the rotor upon brake engagement, generating the necessary friction to decelerate the vehicle. The NBK D6994H brake pads, for instance, are crafted to slot seamlessly into the caliper, ensuring efficient and safe operation. The rotor, a disc linked to the wheel, is crucial to the system's efficacy, with the quality of the pad-rotor contact being paramount.

Materials and Properties of NBK Brake Components

The selection of materials for NBK brake components is predicated on their resilience and capacity to perform under duress. NBK brake pads and shoes are typically fashioned from premium metals, ceramics, and composite substances. These materials are designed to resist the high temperatures and friction encountered during use, guaranteeing sustained effectiveness of the brakes. For example, the NBK D6247 FF brake pads may utilize a ceramic blend that offers quieter operation and diminished brake dust, contributing to their popularity among drivers and manufacturers alike.

Business Usages and Applications of NBK Brakes

NBK brakes find their application in a multitude of industries, ranging from vehicle production to the aftermarket sector and maintenance services. Within the logistics realm, dependable braking systems such as those provided by NBK are essential for the safety of heavy-duty trucks and transport vehicles. The NBK brake shoes are especially prized in commercial environments where vehicles undergo frequent stops and carry substantial loads, necessitating sturdy brakes that consistently perform without the need for regular replacement. These brakes have become invaluable in upholding the operational efficiency and safety of business activities.

Functions and Tasks of NBK Brake Systems

The foremost role of NBK brake systems is to facilitate the secure deceleration and halting of vehicles. They are adept at transforming kinetic energy into thermal energy via friction, with responsibilities encompassing emergency halts, controlled slowing on descents, and routine stops at traffic signals. The NBK D6272 FF brake pads, to cite an example, are engineered to execute these functions with unwavering dependability, offering steadfast braking force across various driving conditions.

Features and Capabilities of NBK Brakes

Key attributes of NBK brakes include their elevated thermal tolerance, resistance to brake fade, and the provision of a solid pedal sensation. These qualities distinguish NBK brakes from their rivals, with offerings such as the NBK D6994H demonstrating exceptional efficacy in both damp and arid conditions. The defining advantages of NBK brakes lie in their sophisticated material formulations and meticulous engineering, which collectively yield superior braking performance.

Benefits and Positive Outcomes of Using NBK Brakes

Employing NBK brakes confers numerous advantages, such as augmented safety through shorter stopping distances, heightened vehicle command, and reduced upkeep costs owing to their robustness. The advantages of fitting NBK brake pads Toyota or other NBK elements include a more serene driving experience, less strain on the braking system, and a greener operation due to lower brake dust emissions.

How to Use and Maintain NBK Brakes

Optimal functioning of NBK brakes necessitates adherence to proper driving practices, like eschewing abrupt stops and allowing the brakes to cool following extensive use. Selecting the appropriate NBK brake components requires consideration of the vehicle's model and usual driving conditions. For upkeep, routine inspections and cleanings are crucial to avert debris accumulation, which can impair braking efficiency. Installations should invariably be conducted by a certified mechanic to guarantee correct brake functionality.

How do NBK brakes enhance vehicle safety?

NBK brakes bolster vehicle safety through their advanced design and material composition. They are devised to yield a high friction coefficient, leading to reduced stopping distances and improved vehicular control during deceleration. This is especially critical in urgent braking scenarios where the caliber of the brake pads can be the difference between a secure stop and a potential mishap.

What makes NBK brake pads stand out in the market?

What elevates NBK brake pads above the competition is their unwavering commitment to excellence and compatibility. With options such as the NBK brake pads Toyota and NBK D6247 FF, they provide bespoke solutions for specific car models, ensuring the brake pads integrate flawlessly and function as anticipated. Furthermore, the incorporation of cutting-edge materials in their makeup strikes a balance between endurance and performance, positioning them as a top selection for both commercial and private users.

How to ensure the longevity of NBK brake components?

To guarantee the extended lifespan of NBK brake components, consistent maintenance is essential. This entails periodic evaluations of the brake pads and shoes for signs of wear, as well as keeping them clean and clear of debris. It's also crucial to operate the vehicle in a manner that doesn't excessively tax the brakes, such as avoiding aggressive driving styles and adhering to recommended carrying capacities. Proper installation and usage, coupled with regular upkeep, will significantly prolong the durability of NBK brake components.