Top categories

Packaging Raw Materials

Plastic Packaging

Paper Packaging

Packaging & Printing Services

Logistics Packaging

Glass Packaging

Pharmaceutical Packaging

Metal Packaging

Other Packaging & Printing Products

Textile Packaging

Packaging Auxiliary Materials

Wooden & Bamboo Packaging

Printing Materials

About products and suppliers

In the fast-paced world of logistics, efficiency is king. As businesses strive to streamline operations and cut costs, one innovation stands out for its simplicity and effectiveness: pallet slip sheets. These thin, yet durable alternatives to traditional wooden pallets are revolutionizing how goods are transported and stored. In this ultimate guide, we delve into the world of pallet slip sheets, exploring their types, applications, and the myriad advantages they offer to warehouse operations. From their environmental benefits to their adaptability across various industries, slip sheets are not just a trend but a smart strategy for modern logistics management.

Understanding Pallet Slip Sheets

Slip sheets are an innovative solution in the realm of commercial shipping, serving as an alternative to traditional wooden pallets. These pallet-sized sheets are crafted from materials such as plastic, heavy laminated kraft paperboard, or corrugated fiberboard. Their primary function is to support goods during transport, and they are often utilized in conjunction with stretch or shrink wrapping to enhance stability. The shift towards more environmentally conscious practices in logistics has seen slip sheets gain popularity, particularly those made from recycled materials. The adoption of palletless shipping methods is on the rise, driven by the cost-effectiveness of slip sheets. In the context of palletless handling, specialized forklift attachments are commonly employed. These tools facilitate the movement and handling of slip-sheeted unit loads without the need for pallets.

Types of Pallet Slip Sheets

Pallet slip sheets are an innovative and cost-effective solution for material handling and storage, offering a variety of types to suit different needs within warehouse operations. The first type is the Single Edge slip sheet, characterized by one tab that facilitates easy handling. This type is particularly useful for lighter loads that require less support.

Adjacent Edge slip sheets come with two tabs located next to each other, providing additional stability for handling goods. This design is beneficial when the direction of loading or unloading is restricted to specific angles.

The Parallel or Opposite Edge slip sheets feature tabs on opposite sides, making them ideal for heavier and bulkier loads. The dual tabs allow for more versatile handling options and balanced support.

Lastly, Multi-Edge slip sheets are equipped with tabs on three or more sides, offering the highest level of flexibility in terms of load support and handling directions. This type is suitable for very heavy or irregularly shaped loads that require support from multiple angles for safe and efficient transport.

Applications in Warehouse Operations

Slip sheets serve as an efficient alternative to traditional wooden pallets in commercial shipping. These thin, pallet-sized sheets are utilized to support goods during transport and are compatible with specific forklift attachments. The adoption of slip sheets is driven by their environmental benefits and cost-effectiveness. Made from materials such as plastic, heavy laminated kraft paperboard, or corrugated fiberboard, they are increasingly being produced from recycled content without compromising on quality. The shift towards palletless shipping methods is also a response to the rising costs associated with wooden pallets. In warehouse operations, the use of slip sheets can streamline processes and reduce material handling costs. They are typically secured with stretch or shrink wrap to maintain the stability of the unit load during movement and storage.

Key Features of High-Quality Slip Sheets

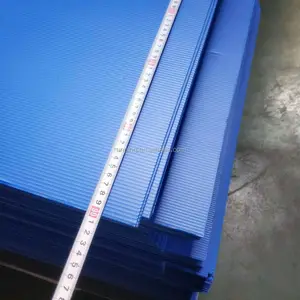

Slip Sheet Pallets are engineered to enhance the efficiency of goods movement by minimizing waste, storage space, and weight. These pallets are constructed from compact fibers, contributing to their durability and functionality.

The design of Slip Sheet Pallets incorporates layers crafted from virgin kraft cardboard combined with a waterproof adhesive. This construction technique bolsters both the longitudinal and transverse strength of the pallets, enabling them to withstand the rigors of transportation without the need for manual unloading.

These pallets are compatible with conventional forklifts, albeit requiring a simple and reversible adaptation. This feature ensures that they can be integrated into existing warehouse operations with minimal disruption.

The adaptability of Slip Sheet Pallets to various customer needs is notable, as they can be customized to meet specific requirements. This flexibility is an essential feature of high-quality slip sheets, ensuring they can serve a wide range of applications in different industries.

Material Choices for Pallet Slip Sheets

Pallet slip sheets are an innovative packaging solution crafted from various materials to cater to different industrial needs. Solid unbleached sulfate (SUS) paperboard is a notable option, predominantly composed of virgin natural wood pulp, and is recognized for its robustness and moisture resistance. This type of paperboard is typically white on one side and is engineered to endure challenging conditions, including moisture.

An economical alternative to SUS is clay coated chipboard, which is constructed entirely from recycled content. While it offers cost savings, it still maintains a level of durability suitable for certain applications. Another variant of SUS paperboard, also derived from a majority of virgin wood pulp, presents a brown finish on both sides, ensuring strength and durability for more demanding uses.

Uncoated chipboard, also made from recycled materials, is tailored to meet specific strength and durability requirements without additional coatings. Lastly, there are thinner sheets available that are valued for their cost-effectiveness, with caliper measurements ranging typically from .08 to .11 point, providing a lightweight yet functional alternative for businesses looking to optimize their packaging process.

Advantages of Using Slip Sheets in Warehouses

Slip sheets offer a cost-effective alternative to traditional wooden pallets, significantly reducing acquisition costs. They are designed to be lightweight, which contributes to lower transportation costs as more slip sheets can be stored in the space of one pallet, and they weigh considerably less.

The use of slip sheets can lead to substantial labor savings. They streamline the loading process, enabling a single worker to load a trailer in a fraction of the time it would take several workers to load using wooden pallets. This efficiency can result in a dramatic reduction in man-hours.

Storage space is optimized with slip sheets, as they occupy less space than wooden pallets, freeing up valuable warehouse area for other uses. Additionally, slip sheets are disposable, simplifying administrative tasks by eliminating the need to track, return, or repair them, unlike their wooden counterparts.

Worker safety is enhanced when using slip sheets since they are easier to handle and do not have the same risk of injury that wooden pallets pose with nails and splinters. Furthermore, slip sheets do not provide a habitat for rodents and insects, helping to maintain a cleaner warehouse environment.

From an environmental perspective, slip sheets are a sustainable choice. They are made from renewable resources and are fully recyclable, supporting waste reduction initiatives and compliance with export pallet platform restrictions.

Maximizing Efficiency with Slip Sheets

In the realm of logistics and warehouse management, the implementation of pallet slip sheets is a game-changer for maximizing efficiency. Our platform offers a diverse range of slip sheets that cater to various operational needs. These slip sheets are designed to streamline the handling and transportation of goods, providing a lightweight yet sturdy alternative to traditional pallets. The selection includes options made from durable materials like HDPE, Kraft paper, and rubber, each serving a specific purpose within the supply chain.

The plastic slip sheets available are particularly beneficial for environments where moisture resistance and hygiene are paramount. They come in various thicknesses, including the commonly used 1.2mm HDPE sheets, which are robust and suitable for heavy-duty applications. For businesses looking to enhance their eco-friendly practices, recyclable Kraft paper slip sheets present an excellent option. These sheets are not only environmentally sustainable but also versatile, being foldable and customizable in size and color to meet specific requirements.

Moreover, the slip sheets are designed with non-slip surfaces to ensure the stability of goods during transport, which is crucial for the safe and efficient movement of cargo. The availability of different sizes and the ability to withstand heavy loads make these slip sheets a practical choice for a wide range of industries. By integrating these slip sheets into warehouse operations, businesses can expect to see a significant improvement in the ease and speed of loading and unloading, ultimately leading to a more streamlined supply chain.

Implementing Slip Sheets in Your Warehouse

Implementing slip sheets in warehouse operations can significantly streamline the handling and shipping process. Slip sheets serve as a cost-effective and efficient alternative to traditional wooden pallets. Their lightweight nature contributes to reduced transportation and handling costs, as they occupy less space and can be easily maneuvered. Made predominantly from recyclable materials, slip sheets are not only an eco-friendly choice but also require minimal maintenance, being reusable for multiple trips.

The adoption of slip sheets in logistics and shipping sectors is gaining momentum due to their ability to keep products free from contamination and ensure enhanced protection during transit. With the expansion of e-commerce and the consequent rise in global trade volumes, the need for reliable and space-saving packaging solutions like slip sheets is more pronounced. They are particularly beneficial in the packaging sector, where the safety and integrity of products during movement is paramount.

For warehouses looking to implement slip sheets, it is essential to recognize their role in reducing handling costs and their contribution to a more sustainable packaging process. As businesses continue to seek out protective packaging solutions that are also cost-effective, slip sheets are becoming increasingly popular. Their recyclability and sustainability further add to their appeal, making them a smart investment for businesses aiming to optimize their warehouse operations and reduce their environmental footprint.

Conclusion

In conclusion, pallet slip sheets represent a transformative approach to warehouse efficiency, offering a myriad of benefits over traditional pallets. Their versatility and cost-effectiveness are evident in the variety of materials and designs available, tailored to meet the diverse needs of industries. The environmental advantages, coupled with the operational efficiencies they provide, such as reduced labor costs, optimized storage space, and enhanced worker safety, make slip sheets an indispensable tool in modern warehousing. As demonstrated, platforms are at the forefront of supplying diverse and quality slip sheets, ensuring that businesses can easily adopt this innovative solution. Implementing slip sheets is more than a logistical decision; it's a strategic move towards sustainability and economic prudence in a competitive global market. As we have seen, those who embrace the use of slip sheets are set to reap significant rewards in the efficiency and sustainability of their supply chain operations.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4