Popular in your industry

Related Searches:

Top categories

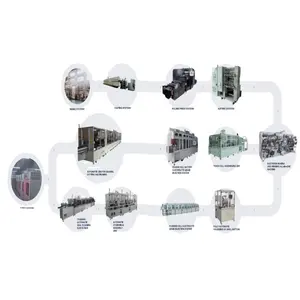

About production line keys

A production line is a sequence of steps involved in manufacturing a product. It combines various machines, tools, and human labor to transform raw materials into finished goods. Each step in the production line is essential for the overall manufacturing process and contributes to the efficiency and quality of the final product. The production line includes various types of equipment, such as conveyors, robots, and assembly stations, that work together to streamline the manufacturing process. A well-designed production line can significantly increase productivity, reduce labor costs, and ensure consistency in product quality. It is a critical component of many industries, including automotive, electronics, and food and beverage.

Types of production lines

There are several different types of production lines, each tailored to the specific needs of the industry and the nature of the products being manufactured. One common type is the assembly line, where workers perform specific tasks in a sequential manner to put together a product. Another type is the continuous production line, which operates 24/7 and is ideal for high-volume manufacturing. Additionally, the batch production line is used to produce a set number of products in a defined quantity before moving on to the next batch. The cellular manufacturing line organizes workers and machines into self-contained units, or cells, to manufacture a specific product or component.

Benefits of a production line

The production line is a key element in the manufacturing industry, and its benefits are far-reaching. It enhances efficiency by streamlining the manufacturing process, reducing the time and resources required to produce goods. It improves product quality by ensuring consistency and precision in each step of production. The production line also enables scalability, allowing manufacturers to increase or decrease production capacity based on demand. Moreover, it minimizes labor costs by automating repetitive tasks and optimizing workforce utilization. Additionally, it enhances workplace safety by reducing manual handling of heavy machinery and hazardous materials. Furthermore, it provides better inventory management by enabling the just-in-time production model, reducing excess stock and warehousing costs.

Applications of a production line

The production line is used across a wide range of industries to manufacture various products efficiently and consistently. In the automotive industry, production lines are integral to the assembly of vehicles, where each step is meticulously planned to ensure a seamless manufacturing process. In the electronics sector, production lines are used to fabricate and assemble electronic components and devices, such as smartphones, computers, and circuit boards. In the food and beverage industry, production lines are employed for the automated processing and packaging of food products, ensuring food safety and quality. The pharmaceutical industry utilizes production lines to manufacture drugs and medical devices with precision and compliance. In the textile industry, production lines are vital for the mass production of clothing and textiles, optimizing the manufacturing process.