(26491 products available)

A sandwich panel garage is a type of building structure made using sandwich panels, which consist of two thin layers of material, usually metal, with a thick insulating layer in between. These garages are known for being light but strong and energy-saving, making them ideal for storing cars and other things. Different kinds of sandwich panel garages are available to meet various needs, and here is a look at some of the common types.

EPS Sandwich Panel Garage

EPS sandwich panels are made of expanded polystyrene (EPS) for their insulation core. The EPS panels are light and have good insulation properties, making them ideal for garages where thermal control is important but where weight matters less.

PU Sandwich Panel Garage

PU sandwich panels use polyurethane foam (PU) as the insulation core. These panels are known for their excellent insulation and relatively thin design. A PU sandwich panel garage could provide much insulation in a small space, making it suitable for areas where insulating thickness is restricted.

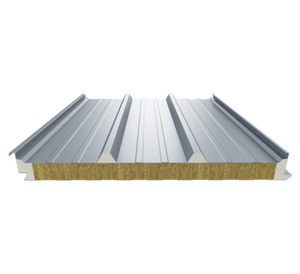

Mineral Wool Sandwich Panel Garage

Mineral wool sandwich panels use mineral wool, also known as rock wool, for their insulation core. These panels are fireproof and have very little noise. A mineral wool sandwich panel garage would therefore be suitable where fire safety and noise control are important, such as near busy roads or in mixed-use developments.

Glass Wool Sandwich Panel Garage

Glass wool sandwich panels use glass wool insulation. These garages are designed to prevent fire and reduce noise. A glass wool sandwich panel garage would be appropriate in places where sound insulation and fire safety are crucial, such as near residential areas or in locations requiring strict building codes.

Roll Up Doors

These garages have a roll-up door for easy vehicle entry and exit. The door rolls up neatly along the top when opened, providing seamless access to the garage space. This design is ideal for tight spaces where swing-out doors may not be practical.

Modular Panel System

The modular panel system allows for customization and expansion of the garage. Users can add more panels later to increase size or change the layout. This design offers flexibility for those who may need more storage in the future.

Integrated Storage Solutions

Garages come with built-in shelves, cabinets, and hooks for tools and equipment. Integrated storage keeps everything organized and easy to access, making the garage more functional as a workshop or hobby space.

Insulated Climate Control

Insulated garages use panels with an insulation core to regulate temperature. This design is suitable for areas with extreme weather conditions. The insulation keeps the garage cool in summer and warm in winter, protecting temperature-sensitive items like wine or electronics.

Eco-Friendly Green Roof

The green roof design incorporates living plants on the garage roof. This eco-friendly option helps manage rainwater, improve air quality, and provide habitat for wildlife. It also offers energy-saving benefits by insulating the building.

Sandwich panel garages are extremely versatile and can be used in a variety of industries. The following scenarios illustrate some of the ways these garages can be used.

Automotive industry

Sandwich garages are widely used in the automotive industry as car workshop garage panels, where they provide a safe and eco-friendly place for repairing vehicles. These garages are usually installed with adequate ventilation systems for the exhaust gases to disperse and special fireproof sandwich panels for the fire risk areas.

Aerospace industry

In the aerospace industry, sandwich panel garages serve as hangars for aircraft maintenance. The panels' lightweight design and high strength make them ideal for spanning large openings required for hangar doors.

Marine industry

Sandwich panel garages are used as boat sheds in the marine industry. These garages can withstand the humid environment characteristic of the coastal areas, thanks to their corrosion resistance and water-proof capabilities.

Logistics and warehousing

In warehouses and distribution centers, sandwich panel garages can be deployed as truck bays or storage facilities for spare parts. Their quick and easy-to-install feature makes them an ideal choice for building garages to accommodate the ever-increasing logistics needs.

Renewable energy sector

With the rapid development of renewable energy, sandwich panel garages can also be found in solar farms and wind farms, serving as maintenance sheds for equipment. The garages' energy-efficient construction helps reduce the carbon footprint of the facility.

Wholesale buyers should evaluate these things when choosing the garages.

Supplier Expertise

The supplier should have a deep knowledge of sandwich panel garages. Ask the supplier about the garages' design, construction, and insulation. The supplier should also know about industry trends and new technologies.

Product Quality and Certifications

Check the garages for relevant certifications. The panels should meet fire resistance and energy efficiency standards. Verify the garage panels with third-party quality certificates. Also, ask the supplier for test reports from independent labs.

Customization Options

Choose suppliers who offer customization options. The garages should have designs to fit different customer needs. Ask about customizations for the panels' thickness, materials, and finishes. Also, inquire about options for adding doors, windows, and ventilation systems.

Shipping and Logistics

Get information about shipping and logistics. Understand the lead times for producing garages. Ask how the supplier will package the panels to prevent damage during shipping. Also, ask about the shipping costs and the available transportation methods.

Customer Support

Evaluate the supplier's customer support. Ensure that they are responsive and can quickly answer questions. Ask about the warranties for the sandwich panel garages. Make sure that the supplier will support the product if there are defects or issues.

Market Demand and Trends

Study the market demand for sandwich panel garages. Pay attention to trends in industrial and commercial construction. Use market research to find out which designs and features are popular. Then, use this information to choose the garages that will sell well.

Q1. What are the benefits of using a sandwich panel garage for storage?

A1. Sandwich panel garages are cost-effective, flexible, and quick-to-build storage solutions.

Q2. How long does it take to construct a sandwich panel garage?

A2. These garages can be constructed within a short period of 4 to 6 weeks.

Q3. Can a sandwich panel garage be easily dismantled and relocated?

A3. Yes, sandwich panel garages can be easily taken down and moved to another site.

Q4. Do sandwich panel garages need any special foundations?

A4. No, they usually require only minimal foundation work, which reduces construction costs and time.

Q5. Are sandwich panel garages fire-resistant?

A5. The fire resistance of these garages depends on the panels used. Some offer good protection against fires.