Popular in your industry

Related Searches:

Top categories

About small scale chapati making machine

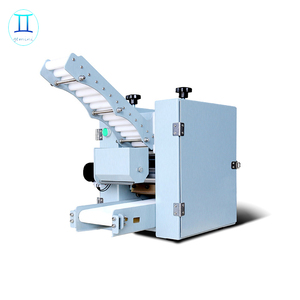

Introduction to Small Scale Chapati Making Machines

The realm of culinary automation has seen significant advancements with the introduction of small scale chapati making machines. These devices cater to the needs of small businesses and kitchens, streamlining the process of chapati production. The machines are designed to be compact, efficient, and versatile, making them an ideal choice for establishments looking to enhance their food preparation operations.

Design and Material Considerations

When it comes to the construction of small scale chapati making machines, durability and hygiene are paramount. Typically, these machines are crafted from high-grade stainless steel, ensuring longevity and ease of cleaning. The choice of materials also ensures that the machines meet food safety standards, which is critical for any food processing equipment.

Operational Efficiency

Efficiency is a cornerstone of the small scale chapati making machine. Designed to optimize the chapati production process, these machines are equipped with features that save time and labor. Their operational design allows for a consistent output of chapatis with uniform cooking and thickness, which is essential for maintaining product consistency in a commercial setting.

Features and Applications

The versatility of a small scale chapati making machine is evident in its various applications. From restaurants to food stalls, these machines are capable of producing a high volume of chapatis without compromising on quality. Features may include adjustable temperature controls, dough thickness regulators, and variable speed settings, which collectively contribute to the machine's adaptability to different production needs.

Advantages of Automation

Embracing automation with a small scale chapati making machine brings numerous advantages. The reduction in manual labor not only streamlines the production process but also minimizes the potential for human error. Additionally, the consistent quality of the output can enhance customer satisfaction, which is crucial for any food-related business.

Environmental and Cost Considerations

Modern small scale chapati making machines are designed with energy efficiency in mind. Their ability to operate on lower power without compromising performance is beneficial for both the environment and the operator's utility costs. Furthermore, the ease of maintenance and the availability of parts contribute to a lower overall cost of ownership.