Understanding Sock Knitting Machine Needle Types

The realm of textile manufacturing is intricate, with sock knitting machine needle types playing a pivotal role in the production process. These needles are the backbone of sock creation, ensuring precision and efficiency in every stitch. The variety of needles available caters to different knitting requirements, from the fineness of the yarn to the complexity of the pattern.

Types and Applications

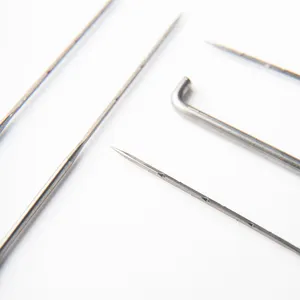

Needle selection for sock knitting machines is vast, with each type designed for a specific function. Weft feeders, weft sensors, and electronic weft selectors are integral for yarn feeding and pattern accuracy. Meanwhile, guide hooks and drive wheels are essential for the seamless movement of yarn through the machine. The correct needle type enhances the machine's performance, impacting the final product's quality.

Features and Materials

The construction of sock machine needles is a testament to modern engineering. Predominantly made from ceramics, these needles offer durability and longevity. Ceramic needles resist wear and are less prone to contamination, making them a reliable choice for continuous operation. Their easy-to-clean nature ensures maintenance is straightforward, preventing downtime due to clogged components.

Advantages of Quality Needles

Investing in the right sock knitting machine parts can significantly enhance production. High-standard needles contribute to uniformity in sock quality, ensuring consistent product output. Flexibility is another advantage, as various needle types can adapt to different knitting patterns and yarn types, broadening the range of socks that can be produced on a single machine.

Considerations for Selection

Choosing the appropriate sock knitting machine accessories requires careful consideration. Compatibility with the existing machinery is crucial to prevent malfunctions and production delays. It's essential to assess the specific needs of your textile machine and the compatibility of spare parts to ensure seamless integration and operation.

Finding the Right Supplier on Alibaba.com

For those in the market for sock knitting machine components, Alibaba.com serves as a comprehensive marketplace. The platform connects buyers with a diverse range of suppliers, offering an extensive selection of needle types to suit various machine models and production requirements. Utilize the search function to explore and compare options that align with your machinery and operational needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4