(44344 products available)

Ready to Ship

Ready to Ship

Market Overview: The global sugar packing machine market is witnessing robust growth, propelled by the increasing demand for packaged sugar products. According to Research and Markets, the market for beverage processing equipment, closely related to sugar packing, is projected to grow from USD 26.81 billion in 2023 to USD 40.85 billion by 2030, reflecting a CAGR of 6.19%. This growth is driven by heightened health consciousness and the rising popularity of low-sugar products, pushing manufacturers to invest in efficient packing technologies. Additionally, the trend towards automation in food and beverage processing is compelling sugar manufacturers to adopt advanced packing solutions that enhance productivity and ensure compliance with stringent industry standards.

Regional Insights: The sugar packing machine market is particularly vibrant in the Asia-Pacific region, where rising disposable incomes and urbanization are fostering increased demand for packaged foods. China, in particular, is positioned for significant growth, reflecting broader shifts in consumer behavior towards convenience and quality. North America, known for its established food processing industry, is also adapting to changing consumer preferences for healthier options, thus influencing the need for innovative packing solutions. Furthermore, the integration of smart technologies in sugar packing machines is emerging as a key driver, offering opportunities for real-time monitoring and predictive maintenance, which enhances operational efficiency and reduces downtime. As manufacturers navigate these dynamics, the focus on sustainability and energy efficiency is becoming paramount, aligning with global trends towards environmentally friendly production practices.

A sugar packing machine is any type of packaging machine specifically for sugar products. It is used to package granulated sugar, powdered, brown sugar, liquid sugar, and any other form of sugar. The packing machines ensure that the sugar is packaged neatly. At the same time, they help maintain quality and prevent spillage. Depending on the kind of sugar to be packaged, various machines are available for different types and packaging needs.

Automatic Sugar Packing Machines

An automatic sugar packing machine is used for mass packaging of sugar. This machine is commonly used by industrial manufacturers. It is usually integrated with feeder systems, sealing controls, and full production line setups. An automatic packing machine comes with multiple packaging modes. It can do pouches, sachets, cartons, jars, bottles, etc. The most common are the sachet and pouch modes. An automatic sugar packing machine is efficient and has high-speed operations. The machine can package up to 80-120 bags per minute. This reduces manual labor. Plus, it provides great accuracy. The sachet usually comes with weights between 1-50kg. However, setups with scale divisions can weigh up to 500kg.

Brown Sugar Packing Machines

These machines are built to package loose brown sugar. Unlike white sugar, which is finer, brown sugar is coarser and moister. As a result, the material needs to be handled gently and carefully to avoid leakage. Usually, they are used for saches and pouches packaging. They come with options for ziplock and tear-not features. Most machines have digital scales and can package up to 1000g of material in under 30 seconds.

Powdered Sugar Packing Machines

The powdered version is very fine and can easily spill or scatter. Typically, these machines come with multiple hopper options and are made with dust-proof features. They also have weighing divisions from 10g to 500kg. Some hoppers even come with excavator feeders for easier packaging of powdery materials like powdered sugar, flour, cocoa, and spices.

Sachet Sugar Packaging Machines

A sachet sugar packaging machine is specifically designed to package sugar in small sachets. Sachet packaging machines automatically fill and seal sugar in single-use sachets. The sachet can be customized in width and height. It is usually made out of paper, plastic, or biodegradable material. These machines are suitable for packaging granulated sugar, brown sugar, and powdered sugar into consumer-friendly sachets for distribution to restaurants, cafes, and foodservice establishments.

The performance of a sugar packing machine largely depends on its specifications. Understanding the specifications is crucial for selecting the appropriate machine and ensuring effective maintenance.

Common specifications to consider include the maximum capacity, packaging types compatible with the machine, and dimensions and weight.

Maximum capacity

This refers to the amount of sugar the machine can pack per unit of time. It is typically measured in bags per minute or hour. Machines with a higher capacity are suitable for high-production environments, while those with lower capacities are more appropriate for small-scale operations.

Packaging types

Languages compatible with the packing type are determined, such as sachets, pouches, jars, and bags. Consider a machine that can handle different kinds of packages if variety is desired. Otherwise, it is better to choose a model that specializes in a particular kind of packaging.

Dimension and weight

A machine's size and weight must be considered since it must fit within the available space. Additionally, transportation, installation, and the ability to move about production facilities all benefit from knowing the weight and measurements.

To ensure optimal performance, it is crucial to maintain the sugar packing machine. Proper maintenance prolongs the lifespan of the device and enhances its efficiency.

Cleaning

Regular cleaning is important to prevent the buildup of sugar residue. Use water and a mild detergent to wipe the machine's surfaces, avoiding harsh chemicals that may cause damage.

Lubrication

Lubricate moving parts such as bearings and chains with machine-specific lubricants to keep the packing machine operating smoothly and reduce friction.

Periodic inspection

For signs of damage or wear, frequently check components like belts, clutches, and sensors. Replace parts that have been damaged to get the packing machine back in working order or to stop malfunctioning.

Calibration

Regularly calibrate the weighing system to ensure accuracy in sugar measurement. This helps maintain packaging consistency and prevent unnecessary product loss.

Training

Conduct training for maintenance personnel to ensure they understand proper handling techniques and maintenance procedures. Proper training minimizes the risk of damage caused by improper maintenance practices.

Sugar industry

Sugar producers frequently utilize these machines as an integral part of their production lines. They aid in the packaging of sugar in a variety of forms such as granules, powder, and cubes. These machines ensure that the final products of the sugar industry are appropriately packed for distribution and sale.

Food and beverage industry

Within the food and beverage sector, a range of items, including but not limited to flavored condiments, baking materials, therapeutic beverages, and coffee mixes, require the use of sugar packing machines. These machines help package sugar to meet diverse product requirements and consumer preferences.

E-commerce packaging and fulfillment centers

Packaging and fulfillment centers for e-commerce have witnessed a rapid surge of online shopping. Consumers increasingly prefer to purchase products such as sugar online, hence the need for efficient packaging machines. Sugar packing machines are capable of handling high-volume orders and packaging products in a way that is suitable for shipping and delivery.

Catering and hospitality industry

The sugar packaging requirements in the catering and hospitality sector vary according to the distinctiveness of the industry. Airlines, hotels, restaurants, and cafes, among others, often require individually packed sugar packets for beverages or as ingredients for recipes. Custom-sized and branded sugar packaging machines can be integrated into service systems to meet the specific needs of the catering and hospitality sector.

Export and international trade

Sugar packing machines play an important role in export and international trade; exports are often the equivalent of bulk or custom-sized packages. These machines can handle different packaging requirements to meet international regulations and standards, such as labeling and traceability.

When purchasing a sugar sachet packing machine, buyers should opt for those with an energy-saving design. Such a machine will minimize power consumption while boosting productivity. Also, consider the machine's packing speed. Depending on the size of the business, the buyer should choose a machine that has a sachet packing speed that aligns with daily production needs.

Ensure the machine has a user-friendly interface. An intuitive and easy-to-use interface simplifies operation, reduces training requirements, and enhances overall efficiency. It is also important to evaluate the machine's adaptability to different types of sugar. Some machines are designed to handle only refined white sugar, while others can package various sugars, including brown sugar, powdered sugar, and artificial sweeteners.

Note that hygiene and cleanliness are paramount in the food industry. Therefore, buyers should choose a machine that is easy to clean and has features that prevent contamination. For example, packing machines with removable parts and smooth surfaces allow for thorough cleaning. Depending on the sugar product, the material choice can affect branding and product perception. Buyers should choose packing machines that can use food-grade packing materials.

Additionally, choose a machine that has adjustable packing weights and can accommodate different sugar quantities. This flexibility is crucial when introducing new products or responding to changing market demands. Finally, since a sugar packing machine is a huge investment, buyers should choose machines that are easy to install and come with excellent after-sale services.

Q: What kinds of packaging can a sugar packing machine accomplish?

A: The sugar packing machine can complete various types of packaging for sugar products, such as powdered, granulated, and crystal shapes. It can use different types of packaging materials, such as flexible packaging, boxes, bottles, containers, or jars, and it can make various packaging styles, such as pouches, sachets, labels, and more.

Q: Is it possible to adjust the amount of sugar in the packet?

A: Yes, the sugar packing machine can adjust weight and sugar amounts according to different customer requirements. It can practice distinct packaging sizes and weights, which is essential for those who want to offer various sugar concentrations or packaging sizes to their clients. Additionally, it is possible to program the machine to change production, which is helpful when doing runs of specific sizes but also when changing to different kinds of sugars.

Q: Can the machine be integrated into an existing production line?

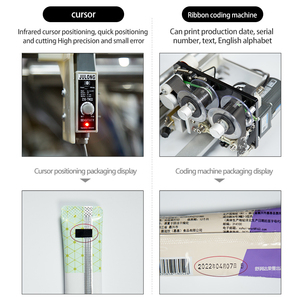

A: Yes, in the great majority of cases; the sugar packing machine can be integrated into an already existing production line. This is because the machine is usually adjustable and versatile, so it can be coupled with other machines to create a more significant production and packaging line. For example, it could be connected to a machine that bags sugar, such as an automated feeder or a label printer. Machines that have been designed for use in industrial settings are usually adaptable and can be integrated with other machines.

Q: What kind of maintenance does a sugar packing machine require?

A: The machine requires periodic cleaning, lubrication, and calibration. Washing is necessary for food safety and cleanliness, while oiling and adjusting helps the machines run smoothly and with good accuracy. A specialist should do the calibrations, including any detailed or more complicated maintenance. Regular cleaning and minor maintenance can be done by the operator.