The phrase "used circular knitting machine in Taiwan" denotes second-hand equipment employed for weft knitting, a technique in which loops are interlaced in a circular or helical arrangement. These devices are prized for their affordability and their capacity to craft an extensive array of knitted textiles.

Types of Used Circular Knitting Machines

Delving into the types of second-hand circular knitting machines on offer, one encounters a range from single to double jersey variants, inclusive of rib, interlock, and jacquard models. Each serves distinct textile patterns and features. Single jersey machines are celebrated for their straightforward operation, typically used in crafting lighter fabrics. Conversely, double jersey machines enable the production of heftier, more resilient textiles. Jacquard machines are indispensable for weaving elaborate patterns, crucial for sophisticated design work in the fabric industry. This assortment of machines allows producers to pinpoint the optimal device for their fabric production goals, enhancing both efficiency and textile quality.

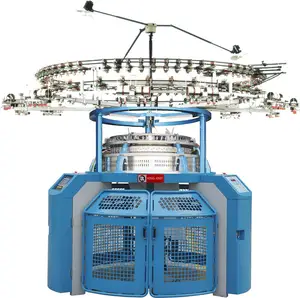

Structure and Operation of Used Circular Knitting Machines

The structure of a pre-owned circular knitting machine is an engineering feat, comprising a cylinder outfitted with needles in a circular configuration. The machine's operation is a symphony of components working in unison. A motor propels the device, activating gears that rotate the cylinder. Yarn is threaded through the needles, looping together to form knitted material as the cylinder spins. The PLC functions as the machine's intellect, granting precise command over the knitting operation, while the gearbox ensures seamless shifts in speed and pattern. The pump and pressure vessel collaborate to sustain the yarn's tension, guaranteeing uniform knitting and averting fabric flaws.

Materials and Properties in Circular Knitting Machines

The materials selected for constructing circular knitting machines are chosen for their endurance and efficacy. Needles and cylinders are often crafted from robust steel, which resists wear and tear, promising durability and consistent quality in textiles. Gears and bearings are typically fashioned from toughened metals to endure the rigors of ceaseless activity. The material choice strikes a balance between cost-efficiency and sustaining high productivity without frequent part replacements or repairs.

Business Usages and Applications

In the sphere of business usages and applications, Taiwan's second-hand circular knitting machines are central to the textile sector. They are deployed in factories for an array of products, from basic t-shirts and undergarments to intricate sportswear and medical textiles. In retail, these machines facilitate the swift production of fashion-forward apparel. Repair shops often refurbish and resell these machines, offering a budget-friendly option for smaller enterprises. The versatility of these machines adds significant business value by allowing manufacturers to swiftly adjust to market shifts and consumer preferences.

Functions of Circular Knitting Machines

The functions of a pre-owned circular knitting machine are manifold. Designed to execute tasks like loop formation, fabric take-down, and pattern generation, these machines can be calibrated to knit various stitches such as plain, tuck, and purl, providing a broad spectrum of textures and fabric attributes. Advanced machines equipped with computerized capabilities can transition between patterns autonomously, markedly boosting production efficiency.

Features of Used Circular Knitting Machines

Notable features of these machines include their rapid knitting prowess, facilitating swift production cycles. Their computerized systems deliver precision control, enabling intricate pattern knitting with minimal error margins. The multifaceted nature of these machines means they can produce diverse knitwear, from flat to tubular and even 3D structures. These attributes give manufacturers a competitive advantage by allowing them to produce top-tier knitwear that satisfies both functional and aesthetic market demands.

Benefits of Investing in Used Circular Knitting Machines

Investing in a pre-owned circular knitting machine brings benefits such as savings on initial outlay, shorter production lead times, and the capacity to manufacture a broad spectrum of products without needing multiple machines. These machines also provide the flexibility to handle various yarn types, which is vital for businesses aiming to diversify their offerings. The high productivity and low upkeep costs contribute to a reduced cost per unit, rendering the production process more lucrative.

How to Effectively Operate a Used Circular Knitting Machine

Effective management of a used circular knitting machine necessitates a grasp of its components and capabilities. Operators must be adept at configuring the machine, including yarn threading and tension calibration. Consistent cleaning and maintenance are essential to avert malfunctions and prolong the machine's service life. When choosing a machine, it's crucial to assess the specific demands of your production, such as the types of textiles you aim to create and the machine's compatibility with your current equipment.

Target Audience and Meeting Their Needs

The target audience for pre-owned circular knitting machines encompasses textile producers, fashion labels, and small to medium enterprises seeking to upscale production without the steep costs associated with new equipment. These machines satisfy the needs of this demographic by striking a balance between performance and cost-effectiveness. They empower businesses to craft high-caliber knitwear that aligns with market trends while keeping overheads manageable.

What are the key selling points of a used circular knitting machine in Taiwan?

The key selling points of a Taiwanese second-hand circular knitting machine include user-friendly operation, high output, and rapidity. These machines are engineered for precision and multifunctional knitting, with low maintenance expenses that render them an appealing choice for businesses intent on optimizing their investment.

What after-sales services can one expect with these machines?

Upon acquiring a used circular knitting machine, purchasers can anticipate extensive after-sales services. Offerings include video technical assistance, online support, and the provision of engineers for overseas service. Such comprehensive support ensures that enterprises can sustain uninterrupted operations with minimal downtime.

How does the computerized feature enhance the knitting process?

The computerized feature of these machines markedly augments the knitting process by ensuring precise regulation of knitting patterns and tension, yielding uniform quality and diminishing waste. This functionality is particularly advantageous for complex designs and patterns that demand exacting precision.

Exploring the selection on Alibaba.com unveils a variety of pre-owned circular knitting machines in Taiwan that cater to diverse business requirements, guaranteeing that you can locate a machine that matches your production needs and budgetary limitations.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4